Aerospace Industry

The development of the aviation industry can not be separated from the strong support of the downstream machine tool industry. The rapid development of the aviation industry will certainly drive and promote the development of the equipment manufacturing industry.

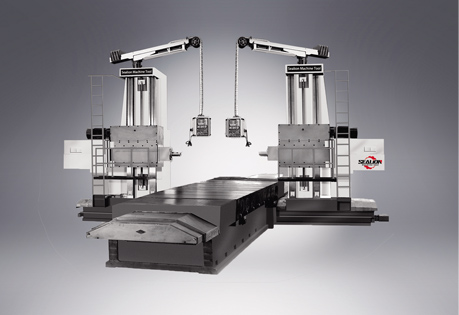

In recent years, with the official launch of China's large aircraft program, Tianjin Aerospace City, and other projects, the demand for a complete set of large-scale precision high-grade CNC machine tools supporting equipment is imminent. In the process of product research and development, our machine tool enterprises focus on the combination with customer applications, in-depth study of the customization process, and constantly launch high-end machine tools to meet customer needs. The high-speed gantry five-axis machining center is the key machining equipment in the high-tech fields such as aerospace, mold, and automobile. The dynamic and static characteristics of the machine tool are important factors affecting the performance of the machine tool, which will indirectly or directly affect the final machining performance of the machine tool; In recent years, the progress of national major projects of high-grade CNC machine tools, many of which involve aviation industry enterprises. For example, WHGS7000 turning-milling complex processing center, gmc2500h / 2x60a five-coordinate crossbeam moving gantry processing center, etc. are respectively applied to Shenfei, Xifei, and other aviation industry-main engine plants. Many parts of aircraft and spacecraft ultimately depend on the processing of machine tools, and the two complements. As a "workmaster" in the equipment manufacturing industry, in the aviation enterprises, it mainly uses large-scale, composite, precise, multi-axis linkage high-grade machine tools, which requires the machine tools to have high rigidity and efficiency, and to cut difficult to process materials, what often used are CNC vertical lathe and vertical turning center, vertical milling machining center, vertical horizontal conversion machining center, CNC boring and milling machine, efficient special blade machining center, tenon forming grinder, CNC EDM machine, etc.

-

The Future of Furniture: Automated Milling Machines in Customized Woodwork

As we step into a new era of craftsmanship, the furniture industry is witnessing a transformative wave, thanks to the integration of cutting-edge technology. At the forefront of this revolution are au... -

Precautions for Using Tools in CNC Milling of Mold Parts

Please pay attention to the following points when choosing a CNC milling cutter for mold milling:1. Face milling cutterFace milling cutters should choose non-heavy carbide end mill or end mill. Genera... -

A CNC Lathe that is Not Free of Programming is Not a Good Lathe

In 2020, in a modern industry with rapid technological development, production and processing will also consume high labor costs and high production costs. The whole process is high consumption and lo...