Causes of Machining Errors and Precautions for Operating a CNC Horizontal Boring Milling Machine

What Are the Reasons for the Machining Errors of CNC Horizontal Boring Milling Machines?

The machining accuracy of CNC horizontal boring milling machine has problems. Is it only a problem with the machine tool itself? Of course not, the problem with machine tool accuracy may also be due to product issues.

However, it is also affected by many factors such as workpiece material, machining process, and environment, which are also one of the reasons affecting the accuracy of CNC horizontal boring milling machines!

Relying on single precision control is easy to produce errors in the machining process, which affects production efficiency. The main reasons for the errors in CNC horizontal boring milling machine machining are as follows:

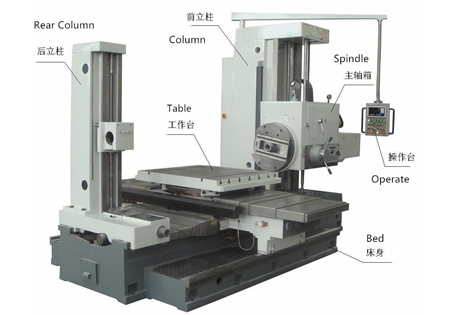

The errors caused by the parts and layout of CNC horizontal boring milling machine during manufacturing and installation, including part size errors and installation errors;

Thermal deformation errors caused by internal and external heat sources of the machine tool;

Deformation errors caused by the weight of the machine tool, cutting force, and vibration errors caused by insufficient dynamic stiffness;

Servo tracking errors caused by machine tool shaft system servo system;

Interpolation errors caused by CNC interpolation algorithm of CNC horizontal boring milling machine;

Other errors, such as environmental errors caused by external vibration, humidity, airflow changes, and testing errors in the detection system.

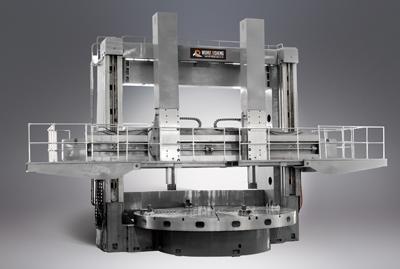

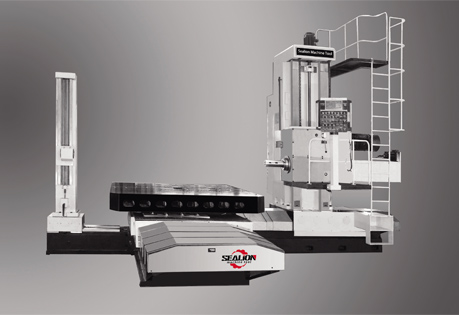

Since the processing of CNC horizontal boring milling machine mainly focuses on processing large parts, milling technology is widely used, and high power and strong cutting are the processing characteristics of this equipment.

Precautions for Operating CNC Horizontal Boring Milling Machine

CNC horizontal boring milling machine has been widely applied in many industries, and these applications have made great contributions to modern industrial production. However, we still don’t know how to use it very well in the application process.

This is because many people have not mastered the use of CNC horizontal boring milling machine. Now let's introduce the precautions to be taken when operating this equipment:

When entering the operation room, you must wear well-fitting work clothes and a work hat. The shirt should be tucked into the pants, and the open sleeves should be firmly buttoned. Female students must tie their long hair into the hat; wearing flip-flops, high-heel shoes, sandals, skirts, shorts, and scarves is strictly prohibited to avoid being burned.

Before running CNC horizontal boring milling machine, check whether the chuck wrench has been removed and whether the machine tool variable speed handle is in the correct position.

It is strictly forbidden to wear gloves when operating CNC horizontal boring milling machine, and the work clothes, collar, and cuffs should be tightly fastened.

It is strictly forbidden to touch the rotating spindle, workpiece, or other moving parts with hands or any other form.

When the various mechanisms of the machine tool are running, the handle cannot be changed. If the handle position is changed, it must be done after parking.

Tools used for clamping workpieces and adjusting cutting tools are strictly prohibited from being placed on the machine tool guide rail.

It is forbidden to install or remove cutting tools during the rotation of the spindle of CNC horizontal boring milling machine.

During automatic processing, it is strictly forbidden to open the machine tool protective door.

It is strictly forbidden to touch the cutting edge and iron filings with hands, and they should be handled with a brush and hook.

During the operation, it is forbidden to play in the workplace.

When a certain job requires two or more people to complete, they should cooperate with each other, and one person must be responsible for safety. Be sure to say hello before starting to avoid accidents.

After the equipment operation is finished, cut off the power supply and clean the iron filings on the work surface of CNC horizontal boring milling machine and the site hygiene.

In industrial production, safety issues should be emphasized, not only for production safety but also for personal safety. Standardized operation of CNC horizontal boring milling machine is an important way to ensure production and safety.

Production safety is not only reflected in the operation of mechanical equipment but also in the words and deeds of workers. Therefore, it is also necessary to standardize their own actions when using CNC horizontal boring milling machine.

-

Some Problems to Notice When Purchasing Milling Machines

For most customers, there is a certain degree of knowledge about the purchase of milling machines. When ordering a milling machine, the equipment parameters, metric and inch system, power supply, volt... -

Principles and Operation of Hydrostatic Boring Bars

In the world of machining, precision and efficiency are paramount. For decades, engineers and manufacturers have sought innovative solutions to improve the accuracy and speed of boring operations. One... -

Maintenance and Operation Procedures for Horizontal Boring Machine

The operator of horizontal boring machine must be familiar with the general performance and structure of the machine, transmission system, and over-performance use is strictly prohibited.Before operat...