Common Alarm and Maintenance of Lubrication System in Machining Center

The alarm of insufficient pressure in the lubrication system of CNC turning lathe center

1. When you manually check whether the pressure meets the requirements. Generally, the insufficient pressure is caused by the oil pipe leaks or the filter screen of the oil pump is too dirty. If there is an external filter, check it, insufficient pressure will occur if the oil is mixed, or sometimes the temperature is too low.

2. It may be that your parameter settings of cnc turning lathe are not appropriate, the interval between oiling is too long, and when the oil pressure is not up, it will detect the oil pressure and cause an alarm. Solution: set the oiling time longer and extend the oil pressure detection time (500ms shorter than oil pumping).

CNC turning lathe center lubrication system maintenance

1. Check the condition of the lubrication system and pressure gauge, clean the filter screen of the lubrication system, replace lubricating oil and dredge oil circuits.

2. Check the gas system, clean the air filter screen, and eliminate the leakage of pressure gas.

3. Check the fluid system, clean the filter, clean the oil tank, replace or filter the oil. If possible, replace the seal.

4. Fasten the transmission parts and replace the defective standard parts.

5. Grease lubrication parts, according to the requirements, add grease

6. Clean the transmission surfaces.

-

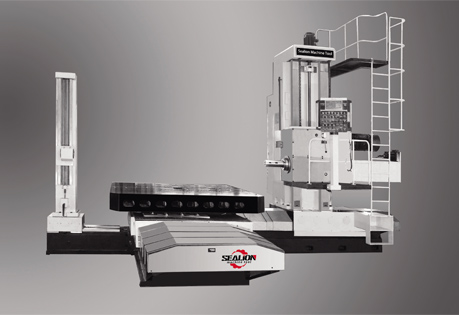

Cutting Capabilities and Machining Operations Performed on CNC Floor Boring Machines

In the world of manufacturing and heavy-duty industries, precision and accuracy are paramount. CNC floor boring machines have revolutionized the way large components are machined, offering enhanced cu... -

Lathe Operation Specifications

1. The operator shall wear the protective equipment correctly according to the regulations. Before processing the old workpieces, remove other things except the processed ones.2. The used/clamp/measur... -

Factors Influencing Coaxiality of Boring and Hole-tuning on Horizontal Boring Machine

The Geometric Errors of Horizontal Boring MachineTo improve the accuracy of the machine tool itself for the requirements of boring holes by turning heads, each item listed in the "Error Table Aff...