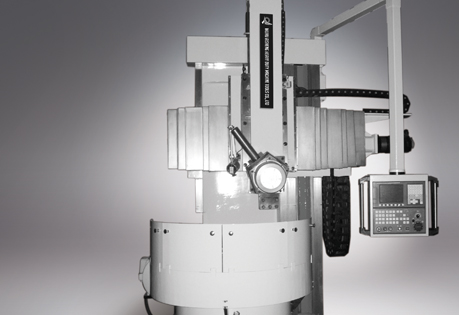

Composition and Working Principle of Cnc Vertical Lathe

CNC vertical lathe machine is a kind of large-scale mechanical equipment, such as cylindrical surface, end surface, conical surface, cylindrical hole, conical hole, etc. of various plates, wheels and casing workpieces.

Accessories can also be used for turning threads, turning spherical surfaces, profiling, milling, grinding and other processing. CNC vertical lathe machines are used to process large and large workpieces with large diameters, relatively small axial dimensions, and complex shapes.

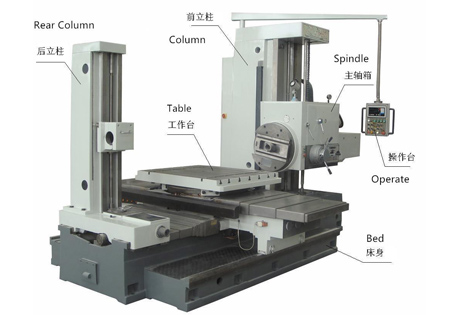

Generally divided into single-column and two-column. A CNC vertical lathe generally consists of a program carrier, input and output equipment, a numerical control (CNC) system, a servo unit, a position detection feedback system, and the main body of mechanical parts of the machine tool.

Ⅰ. The basic working principle of CNC vertical lathe machine

According to the pattern and technical plan of the processed part, the numerical control device decodes and calculates the program (code), and then sends signals to the servo mechanism and auxiliary device of each coordinate of the machine tool, and compiles the processing program in the form of specified code and program.

The compiled processing program is input into the CNC device of the CNC vertical lathe machine; it drives the moving parts of the machine tool, controls the necessary auxiliary actions, and then processes the qualified parts.

Ⅱ. The components of CNC vertical lathe machine

1. Program carrier (control medium)

The control medium refers to the information carrier that sends the processing information of the parts to the CNC device of the vertical lathe through the input device. The control medium, according to the type of the CNC device, often uses punched paper tape, punched card, magnetic tape, disk, etc.

2. Input device

Read the processing-related information in the program carrier into the numerical control device

3. Numerical control device

The output device sends the instructions issued by the control calculator to the servo system, and drives the CNC vertical lathe machine to complete the corresponding actions after power amplification.

4. Servo system

The servo system is the executive mechanism of the CNC vertical lathe, which moves the moving parts of the machine tool or performs some actions according to the requirements of the instruction information, including two major parts: drive and execution. The servo system receives instruction information from the CNC system.

5. Position feedback system

6. The main body of the machine tool

The machine tool body is the body of the CNC machine tool. Except for some economical CNC lathes that basically maintain the traditional configuration of ordinary lathes, it is used to complete various mechanical parts for cutting. At present, most CNC vertical lathe machines have been professionally designed and produced.

7. Spindle and headstock

Spindle: The rotation accuracy of the spindle of the CNC vertical lathe machine directly affects the machining accuracy of the parts; its power and speed affect the processing efficiency; its synchronous operation, automatic speed change and directional quasi-stop affect the degree of automation of the lathe.

Spindle box: CNC vertical lathe machines with step-by-step automatic speed regulation function, there is no mechanism that plays the role of mechanical transmission speed change and direction change, and its spindle box has become synonymous with "shell" and "lubricating box".

The transmission mechanism in the spindle box has been greatly simplified; for CNC lathes with stepless automatic speed regulation (including directional quasi-stop), for modified CNC vertical lathes (with dual functions of manual operation and automatic control processing), the original Some headstocks.

8. Guide rail

The guide rail of the CNC vertical lathe machine is an important part to ensure the correctness of the feed movement. Except for some CNC lathes that still use the traditional slide rails (metal type), the CNC lathes that have been finalized and produced have adopted many plastic-coated guide rails.

Seriously affect the rigidity, precision and stability of the lathe at low-speed feed, and is one of the important factors affecting the processing quality of parts. This new type of slide rail has a small friction coefficient, good wear resistance, corrosion resistance and vibration absorption, and good lubrication conditions.

9. Mechanical transmission mechanism

In addition to some gear transmission and other mechanisms in the spindle box, the CNC vertical lathe machine has been greatly simplified on the basis of the original ordinary lathe transmission chain.

Screw transmission mechanism The screw pair in the CNC lathe is a motion pair that converts the rotational motion output by the drive motor into the longitudinal and lateral linear motion of the tool post. The components that constitute the screw transmission mechanism are generally ball screw pairs.

The above is the composition and working principle of the CNC vertical lathe machine. If you need to know more, please feel free to contact us!

-

Underground Engineering: Exploring the Versatility of Horizontal Boring Mills in Tunneling Applications.

Tunneling has been a crucial method in various industries, from infrastructure development to mining operations. To achieve precision, efficiency, and safety in tunneling projects, advanced machinery ... -

Essential Maintenance and Troubleshooting Tips for Horizontal Lathe Machines

Horizontal lathe machines play a crucial role in various industries, enabling the precision shaping and machining of components. As with any machine, regular maintenance and the ability to troubleshoo... -

Don't Underestimate the Lathe Tool Collision! Sealion Tells You Three Reasons and Preventive Measures for Lathe Collision!

Lathe collision can be regarded as a major event or as a trivial event. Once the machine tool collision occurs, hundreds of thousands of tools may become waste in an instant. In addition, the machine ...