Maintenance and Operation Procedures for Horizontal Boring Machine

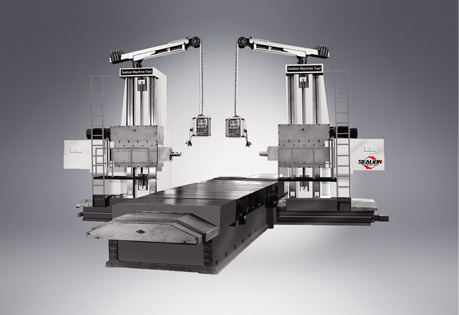

1. The operator of horizontal boring machine must be familiar with the general performance and structure of the machine, transmission system, and over-performance use is strictly prohibited.

2. Before operating the horizontal boring machine, carefully check whether the equipment spindle box and gearbox are normal, whether there is any abnormal noise, whether the guide rail surface is damaged, and whether the lubrication is good, and whether the speed control is sensitive and reliable. Check whether the motor is running and the grounding device is normal and good.

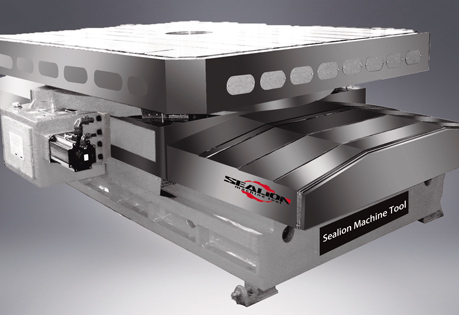

3. According to the lubrication chart, the horizontal boring machine should be oiled as required, and the oil pool and oil hole should be closed after oiling to ensure sufficient lubrication of the boring bar and tailstock bearings. Check whether the oil level and oil flow are up to standard.

Regularly clean the oil felts, oil lines, and oil filters (barrels) of the horizontal boring machine to keep the oil tank and oil pool clean and the oil quality good.

Before starting the horizontal boring machine, low-speed idling for 5 minutes to confirm that all parts are running normally before starting to work.

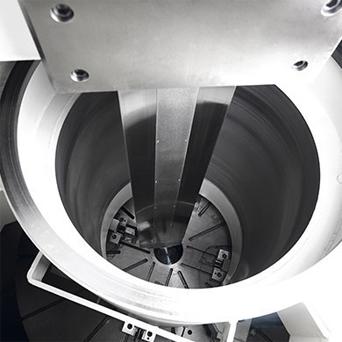

Frequently keep the boring bar of the horizontal boring machine clean and good, and install and remove the tool with standard oblique iron and copper hammer. The oblique iron installed in the boring bar must be 1-3mm below the surface of the boring bar.

When loading and unloading the workpiece on the horizontal boring machine, safe lifting equipment and methods must be selected according to the shape and weight of the workpiece, and it must be lifted and lowered lightly to prevent damaging or colliding with the machine.

When tightening the workpiece on the horizontal boring machine, the pressure of the bolts should be appropriate, and sleeves should not be added for tightening.

When the main spindle of the horizontal boring machine is raised and lowered, and the workbench rotates, the clamping mechanism should be loosened first. After the lifting and rotation are completed, immediately clamp it. It is strictly forbidden to lift and rotate it with the clamping mechanism in the clamped state.

It is not allowed to put the movable handle of the workbench, sliding saddle, sliding plate, spindle box, and boring bar of the horizontal boring machine in the movable position to drive it quickly.

The horizontal boring machine must not use the method of reverse driving the parts. When using the braking device, it should be stopped several times according to the speed. During work, check and remove the iron filings and oil stains on the upper and lower sliding plates, workbench, and guide rail frequently.

Frequently keep the machine tool of the horizontal boring machine clean and in good condition, and store the accessories properly.

After the work of the horizontal boring machine is completed, the workbench must be moved to the bed tail position, the spindle box must be lowered to the lower position, the boring bar must be retreated to the limit position, all handles should be placed in the non-working position, and the power should be cut off. Clean up the iron filings, wipe the surface of the machine tool and guide rail, add lubricant to the guide rail, and carefully fill out the shift handover record and do the handover work well.

-

Rotary Resilience: The Importance of Rotary Tables in Heavy Machinery Manufacturing

In heavy machinery manufacturing, precision, efficiency, and versatility are the bedrock of success. One often-overlooked tool that plays a critical role in achieving these goals is the rotary table. ... -

The Three "High" in the Production of CNC Milling Machine Shafts

The CNC milling machine has the characteristics of high precision, high efficiency and high flexibility. The use of the CNC milling machine can improve the efficiency of shaft processing and create mo... -

Introduction and Classification of Vertical Machining Center

1. Introduction of Vertical Machining CenterVertical machining center refers to a machining center with the main shaft axis and the worktable perpendicular to it. It is mainly suitable for processing ...