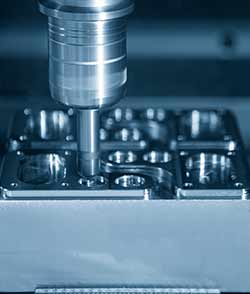

Method of Eliminating Oscillation in CNC Horizontal Boring Milling Machine and the Requirements for Spindle Components

How to Eliminate Oscillation of CNC Horizontal Boring Milling Machine?

There are many factors that cause oscillation in CNC horizontal boring milling machine. In addition to the mechanical factors such as uncontrollable transmission clearance, elastic deformation, and friction resistance, the influence of servo system parameters is also a key aspect.

Reduce position loop gain

The proportional integral controller is a multi-functional controller that not only effectively provides proportional gain to current and voltage signals, but also adjusts the output signal lag to lead. The oscillation fault of CNC horizontal boring milling machine sometimes occurs due to the phase lag to lead of the output current and voltage. In this case, the PID can be used to adjust the phase of the output current and voltage.

Oscillation caused by closed-loop servo system

Some CNC servo systems use a semi-closed loop device, while full-closed loop servo systems must adjust parameters on the premise that local semi-closed loop systems do not produce oscillation. Therefore, the two are similar.

Use the high-frequency suppression function

The above discussion is the parameter optimization method for relevant low-frequency oscillations. Sometimes the CNC system of CNC horizontal boring milling machine will produce feedback signals with high-frequency harmonics due to some mechanical oscillation factors, which makes the output torque non-constant, resulting in vibration. For such high-frequency oscillations, a first-order low-pass filter is added to the speed loop, that is, a torque filter.

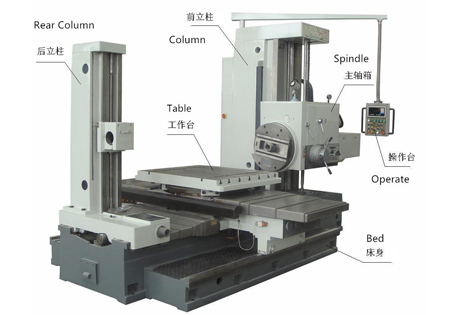

Requirements for Spindle Components of CNC Horizontal Boring Milling Machine

The rigidity of the spindle assembly of the CNC horizontal boring milling machine is the ability of the collecting ring to prevent deformation of the spindle assembly. The greater the rigidity of the components, the greater the rigidity of the spindle assembly, and the smaller the rigidity of the spindle assembly, the smaller the rigidity of the spindle assembly.

The main spindle of CNC horizontal boring milling machine will produce considerable elastic deformation under the action of cutting force and tower frame, which will not only affect the payment of the workpiece, but also damage the normal condition of the axis and bearing, and the normal wear and tear of the axis is accelerated, and the accuracy is lowered.

The rigidity around the main bearing is related to the structure size of the main spindle, the type of bearing selected and its configuration, and the adjustment of the bearing clearance is only related to the position of the original parts when the main pump is pulled up.

Strong needle

The anti-vibration performance of the main spindle assembly of CNC horizontal boring milling machine refers to the ability of the main spindle to maintain vibration-free rolling motion during the cutting process. If the anti-vibration performance of the main spindle assembly is poor, bearings with higher damping ratio are usually used.

If necessary, CNC horizontal boring milling machine should be equipped with a pressure ring so that the inherent frequency of the main spindle assembly is much higher than the excitation frequency.

Low temperature rise

The high temperature rise during the operation of the spindle components will result in poor results, which means that the spindle assembly and box of CNC horizontal boring milling machine will wear due to thermal expansion.

The relative position of the rotation center line of the main spindle to other parts of the machine tool directly affects the machining accuracy, but the original price of the bearing.

Due to the high temperature, the selected clearance will be changed, the normal lubrication condition will be damaged, and the normal operation of the bearing will be affected. In order to solve the temperature rise problem of CNC horizontal boring milling machine, a constant temperature spindle box is often used.

Good wear resistance

The spindle assembly of CNC horizontal boring milling machine must have sufficient internal mold to maintain the accuracy for a long time. The place where the tool or workpiece is installed and the motion is the working surface of the main spindle of the CNC horizontal boring milling machine.

-

The 16th China International Machine Tool Exhibition (Cimt2019) Was Held In Beijing

On April 15, 2019, the 16th China International Machine Tool Exhibition (cimt2019), sponsored by China Machine Tool Industry Association and co sponsored by China International Exhibition Center Group... -

Characteristics of Chinese CNC Lathe

Today, cnc lathe machine China has the following characteristics.The core CNC technology is more intelligent. It is reported that in the new industrial exhibition, the intelligent control system of CN... -

Operating Skills and Experience of CNC Lathe

Ⅰ. Programming skills of CNC latheBecause of the high accuracy requirements of products, we need to consider the following points when processing sequence of parts:1. Drill first and then flat end (t...