Shipbuilding Industry

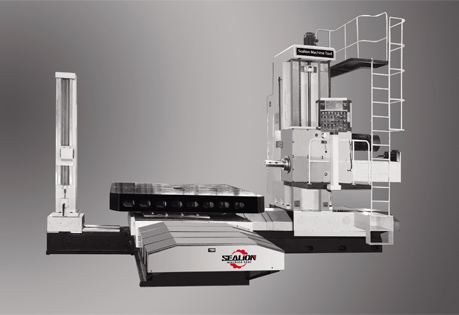

China's shipbuilding volume has been at the forefront of the world. With the development of the shipbuilding industry, the demand for the machine tool industry has increased significantly, which provides a rare business opportunity for the development and improvement of the machine tool industry in China. Therefore, it is urgent to solve the problem of high-grade CNC machine tools, especially the heavy and precise CNC machine tools. China's shipbuilding enterprises are mainly concentrated in Bohai Bay, Yangtze River Delta, and Pearl River Delta. Requirements for large-scale shipbuilding equipment: the machining of the engine base, frame, crankshaft, connecting rod, cylinder head, propeller, rudder shaft, and other large parts of the medium and low-speed diesel engine is the key point for the shipbuilding enterprises to invest in technological transformation equipment. The processing equipment is mainly CNC gantry boring and milling machine and gantry machining center. It is required that the gantry width is not less than 8m, positioning accuracy ≤ 0.016/1000mm, and repeated positioning accuracy ≤ 0.01mm. The main processing equipment of diesel engine connecting rod, crank, cylinder head, and other parts are CNC gantry boring and milling machine, large CNC vertical lathe, Heavy CNC sleeper, and horizontal machining center. The key supporting equipment of modern large-scale ships has large geometry size and high precision requirements, so it requires large specification, high power, large torque, and high precision of processing equipment. The main processing equipment of diesel engine connecting rod, crank, cylinder head, and other parts are CNC gantry boring and milling machine, large CNC vertical lathe, Heavy CNC sleeper, and horizontal machining center. The key supporting equipment of modern large-scale ships has large geometry size and high precision requirements, so it requires large specification, high power, large torque, and high precision of processing equipment. For example, at present, the largest diameter of propeller that can be machined in China is 9 M. with the development of large ships, it is necessary to have a 7-axis 5-linkage CNC milling machine capable of machining 11 m-diameter propeller, and higher requirements are put forward for machining accuracy and surface roughness. Modern large ships require higher propulsion efficiency, lower noise, and higher machining accuracy of key supporting equipment such as a propeller. Therefore, it is necessary to use a turning-milling compound machine tool to complete the one-time forming. For example, the machining of the hub inner hole and thread is realized by turning, and the machining of the propeller blade surface and blade back is completed by milling. The equipment used to process the large-scale low-speed diesel engine base and frame not only needs high power and torque of the main shaft, but also needs high processing accuracy, and is equipped with corresponding testing equipment. The machining of low-speed diesel engine crankshaft mostly adopts CNC heavy turning-milling compound machining center, which requires a large turning diameter and a bearing capacity of nearly 100t.

-

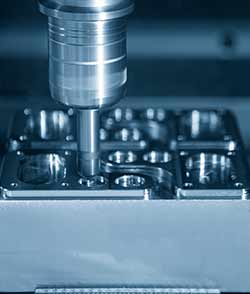

Mould

Mould is the basic industry of national economy, and the development level of mould industry represents the industrial development level of a country in a sense. CNC machine tools are suitable for mac... -

Classification of CNC Machine tools According to Control Mode

1. Open-loop control CNC centre latheThis kind of machine tool does not have the position detection feedback device and usually uses the stepping motor as the actuator. The input data is processed by ... -

Green Precision: Sustainable Practices with Automated Milling in Eco-Friendly Production.

In the modern era, sustainability has become a pressing concern for industries all around the world. With the ever-increasing focus on environmental conservation, businesses are constantly seeking inn...