Three Forms of CNC Lathe Spindle

The precision, stiffness and thermal denaturation of CNC lathe spindle parts directly affect the machining quality. These effects are exacerbated by the fact that CNC lathes do not require manual adjustments during machining. At present, there are three main types of CNC lathe spindles.

1. Double row short cylindrical roller bearing and 60° angular contact double row radial thrust ball bearing

The front support of the CNC lathe is composed of double row short cylindrical roller bearings and 60° angular contact double row radial thrust ball bearings, and the rear support is equipped with pairs of radial thrust ball bearings. The structure greatly improves the overall rigidity of the spindle, can meet the requirements of strong chips, and is widely used in various CNC lathes of small CNC lathe manufacturers.

2. High precision double row angular contact ball bearings and single row (or double row) angular contact ball bearings

The front bearing of CNC lathe adopts high-precision double row angular contact ball bearing, and the rear bearing adopts single row (or double row) angular contact ball bearing. This configuration has good high-speed performance, but its load-carrying capacity is small, so it is suitable for high-speed, light-load and precision CNC lathe spindles.

3. Double and single row tapered bearings

Double row and single row tapered bearings are used for front and rear bearings. This structure limits the high-speed and precision of the spindle, and is suitable for the spindle of medium-precision, low-speed, and heavy-duty CNC lathes.

The simple CNC lathe formed by transforming the feeding system of the ordinary lathe by stepping motor and single-chip microcomputer has low cost, but the degree of automation and function is poor, and the turning accuracy is not high. For low-demand rotating parts.

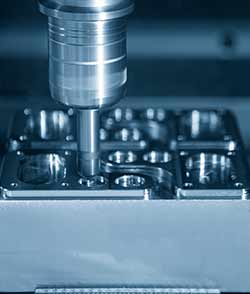

According to the turning requirements, the CNC lathe is specially designed and equipped with a general CNC system. The CNC system has powerful functions, high automation and high machining accuracy. It is suitable for turning of general rotary parts. A CNC lathe can control two axes simultaneously, the X axis and the Z axis.

The Sealion machine is a machine tool specialized in metal cutting and machining. Our products include various machine tools from South Africa, Malaysia, Korea, Indonesia, Singapore, Thailand, Italy and other countries. In addition to 7/24 after-sales service, we also provide our customers with professional customer service and customized technical support. Sirion Machine Tools is constantly innovating and offering turnkey solutions for production lines and individual machines.

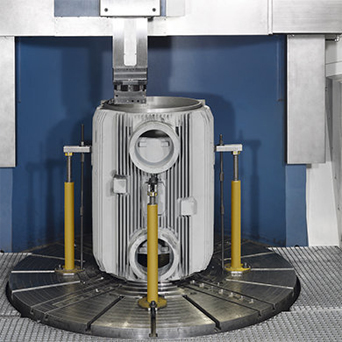

Shanghai Sealion Machine Tool specializes in lathes, turntables, CNC machining centers for vertical and horizontal boring and milling machines. The production base is located in Wuhu, Anhui. Based on a factory building of 30,000 square meters, we strive to meet the various needs of customers. We adhere to the principle of "Quality, Efficiency, Honesty, and Practical Work" to provide you with high-quality processing services. Our company culture is centered on our motto "Customer Service, Customer Support, Customer Choice". We are committed to continuously introducing advanced technology to the industry and work closely with our CNC machine tool manufacturers. We are committed to development to improve quality and maintain production time for our customers. Warmly welcome you to visit our company or contact us for cooperation.

-

Exploring CNC Machining Center Suppliers: Finding Your Manufacturing Partner

In the world of precision manufacturing, CNC machining centers are the backbone of efficiency, accuracy, and versatility. However, the quality of the machining center you choose depends greatly on the... -

Quality and Stability in Floor Type Horizontal Boring Machines

When it comes to floor type horizontal boring machines, quality and stability are key factors that can greatly impact the efficiency and accuracy of drilling operations. These machines are essential f... -

Automobile manufacturing industry

Automobile manufacturing industryThe automobile industry is the locomotive driving the development of machine tool industry. The whole automobile manufacturing industry tests the overall level of prec...