What Machining Center is Good for Machining Box Parts?

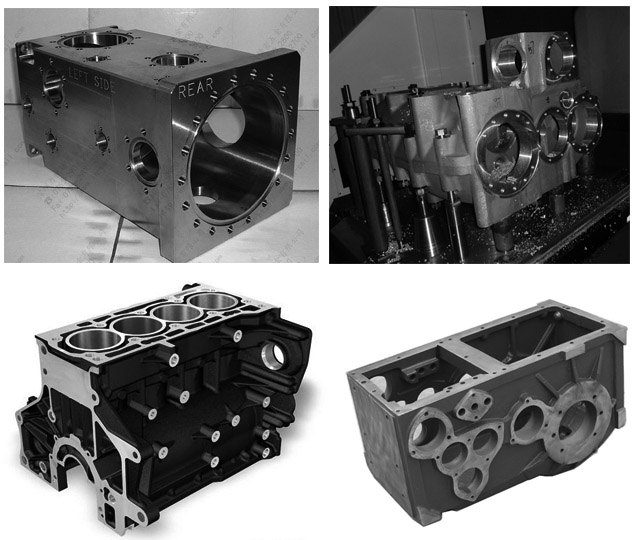

The commonly processed box-type parts generally include the engine cylinder on the automobile, the transmission gearbox, and the transmission gearbox. The following pictures are all parts of the box type.

CNC horizontal machining center is the best choice for machining box parts because the CNC horizontal machining center usually has three linear coordinates and a table rotary shaft, which can complete 80% - 90% of the processing content of multiple surfaces in one clamping of box-type parts. The one-time clamping has small error, high precision, and stable quality. At the same time, it can shorten the production cycle and reduce production costs. Using a horizontal machining center to process box parts has good chip removal ability, while large vertical machining centers and gantry machining centers have poor chip removal ability, which will lead to serious damage and deformation of parts and tools.

Box type parts generally need to carry out hole series, contour, plane multi-station processing, usually through milling, boring, drilling, expanding, reaming, tapping, and other processes, the use of more tools, tooling. In the ordinary machine tools, they have to go through repeatedly clamp, alignment, more measurement times, longer processing cycle, higher cost, while the most important is that the accuracy is difficult to guarantee.

-

The Future of Furniture: Automated Milling Machines in Customized Woodwork

As we step into a new era of craftsmanship, the furniture industry is witnessing a transformative wave, thanks to the integration of cutting-edge technology. At the forefront of this revolution are au... -

From CNC Lathe to Lathe Accessories, How are They Produced?

CNC lathes are the main equipment engaged in machining today. During processing, the machine tool automatically positions and feeds according to the pre-input program, and completes the cutting of par... -

Navigating Precision: Rotary Table Applications in Navigation and Instrumentation Systems

In the intricate world of navigation and instrumentation systems, precision is not just a desired attribute but a critical necessity. Sealion, a pioneer in engineering solutions, has brought forth inn...