What You Should Pay Attention to During the Use of CNC Lathe

CNC lathes are the products of comprehensive high-tech applications such as computers, automatic control, automatic detection, and precision machinery. It is a typical mechatronics processing equipment with high technology density and high degree of automation. Compared with ordinary machine tools, it not only has high precision parts, stable product quality, and extremely high degree of automation, it can reduce the manual labor intensity of workers, greatly improve production efficiency, and can complete the processing of complex curved parts that are difficult or impossible to process on ordinary machine tools. However, we must clearly realize that whether the above-mentioned advantages of CNC machine tools can be realized depends on whether the operator can use them correctly in production. From the operator's point of view, the following precautions in the use of CNC machine tools are discussed to ensure that the advantages of CNC machine tools are fully utilized.

1. Improve the overall quality of operators

The use of CNC lathe is more difficult than the use of ordinary machine tools, because CNC lathe is a typical mechatronic product. It involves a wide range of knowledge, that is, the operator should have a wider range of professional knowledge, such as mechanical, electrical, liquid and gas. Therefore, it requires high quality of operators. At present, a phenomenon that cannot be ignored is that there are more and more users of CNC lathe, but the utilization rate of machine tools is not high. In addition to the incomplete production tasks, there is a more critical factor, that is, the quality of the operators is not high enough and they don't know how to deal with some of the problems encountered. Especially for newly-purchased machine tools, due to factors such as the quality of electronic components and the influence of vibration during transportation, the numerical control system has some failures within 3-6 months of formal production. It is often not found in the maintenance manual, or may have never been encountered before. This requires users to have high quality, be able to deal with problems calmly, have a clear mind, have strong on-site judgment ability, and of course have a solid foundation of CNC.

Generally speaking, when purchasing a new machine tool, the machine tool manufacturer will provide users with technical training opportunities. Although the training time is not long, the training is highly targeted and users should pay attention to the content of the training. The dispatched personnel should include future CNC machine operators. The improvement of the overall quality of operators is not a problem that can be solved at one time or two, but should be accumulated in future use. Another method worth trying is to visit some old users of similar machine tools. They have rich practical experience and the greatest voice. You can ask for their help and ask them to train operators. This is the most effective way to improve the overall quality of operators in a short time.

2. Follow the correct operating procedures

No matter what machine tool, it has its own set of operating procedures. It is not only one of the important measures to ensure the safety of operators, but also an important measure to ensure the safety of equipment and product quality. The user must follow the operating procedures correctly. If the CNC lathe is used for the first time or has not been used for a long time, let it idle for a few minutes first, and pay attention to the order and precautions of turning on and off during use. Especially beginners should pay enough attention to these, because they lack the corresponding operation training and often make mistakes in this regard.

3. Create a good use environment

Generally speaking, the use environment of CNC lathe does not have any harsh requirements, and it can be placed in the same production workshop as an ordinary machine tool. Even so, because CNC machine tools contain a large number of electronic components that are most afraid of direct sunlight, moisture, dust, and vibration, electronic components may be corroded and deteriorated or cause short circuits between components, causing the machine tool to fail to operate normally. These are generally paid attention to when installing the machine tool. For users, the main thing is to pay attention to the protection of the surrounding environment. For example, in rainy days, be careful not to bring umbrellas to the production site or change shoes.

-

Crafting The Future: Automated Milling In Artistic And Sculptural Creations

Art and technology have long danced together, creating harmonies that push the boundaries of human creativity. In the realm of artistic and sculptural creations, a new player has emerged—automated mi... -

How to Operate the CNC Lathe?

1. CNC lathe processing sequenceIn the process of CNC lathe processing, the processing objects are complex, especially the shape and position of some contour curves, and the difference in materials an... -

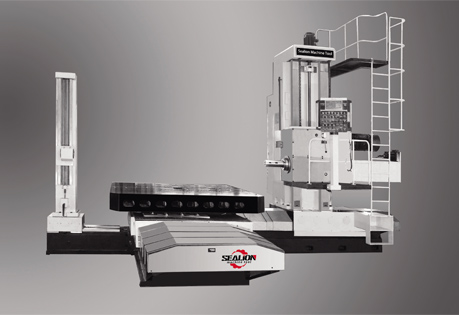

Daily Maintenance and Care for Horizontal Boring Machines

Horizontal boring machine is the main equipment for processing large box parts. In the daily maintenance of the boring machine, the main focus is on cleaning, lubrication, and reasonable operation.The...