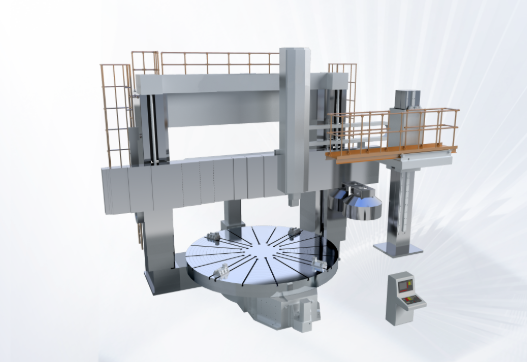

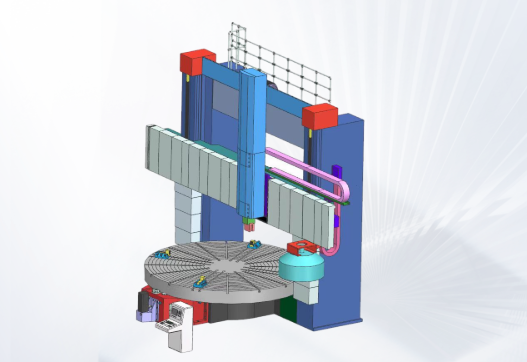

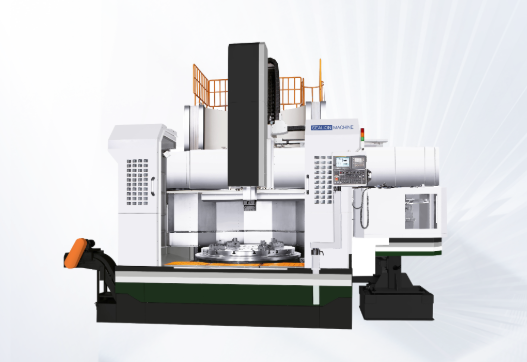

This series is based on a dual lift high-speed vertical latheand coming with milling and drilling functions.

The spindle adopts PSL roller bearing structure, which has higher precision and more compact structure.

The C-axis indexing adopts dual servo motors for clearanceelimination, providing higher stability.

C-axis indexing use encorder to improve indexing accuracy.The Caxis drive adopts an imported dual speed gearbox to provide greater driving force, with a low backlash structure to ensure indexing accuracy.

SP axis drive adopts imported servo motor, providing greatertorque.SP axis is equipped with an encoder to ensure the accuracy of the milling head position.

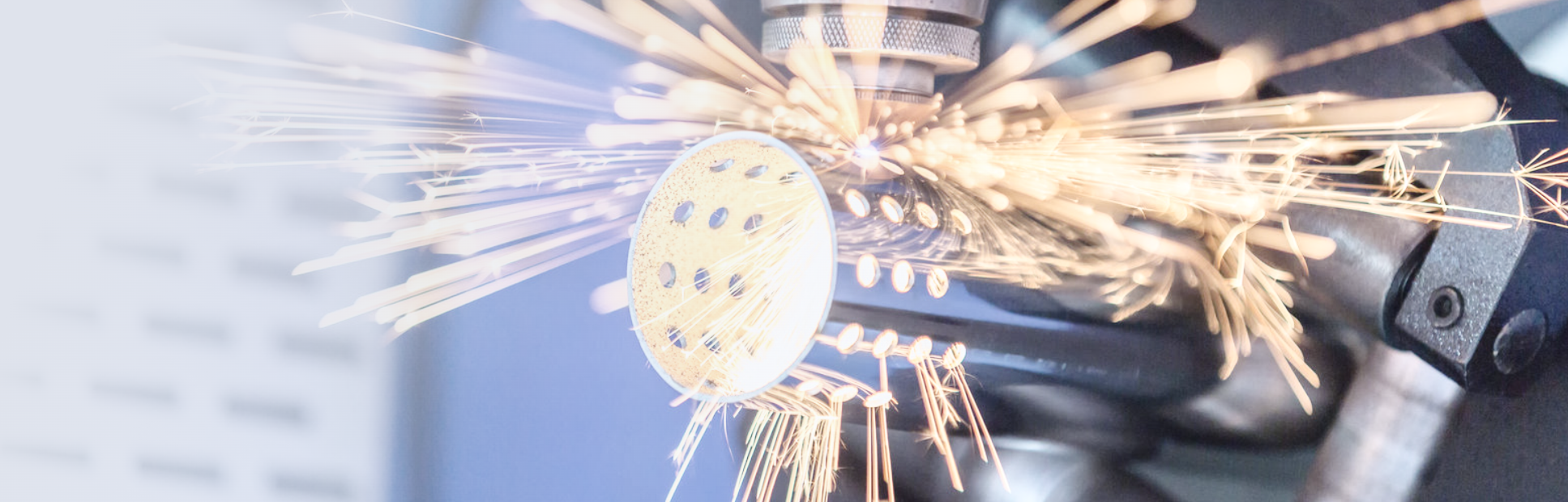

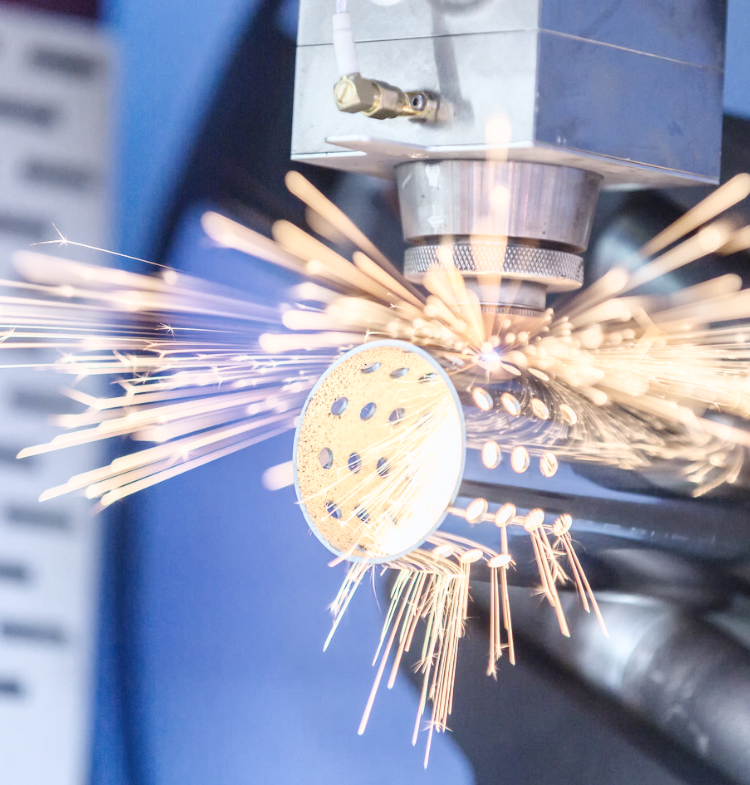

The tool magazine is with BT50 tool holders, for both turning and milling or drilling function.

Unlike previous machining centers, the tool holder is fixed with endface keys to prevent rotation.The ram also equipped with 4 BURG cutting cylinders, which can grip powerful turning tools and effectively resist the torque caused by turning.

Coolant through spindle.

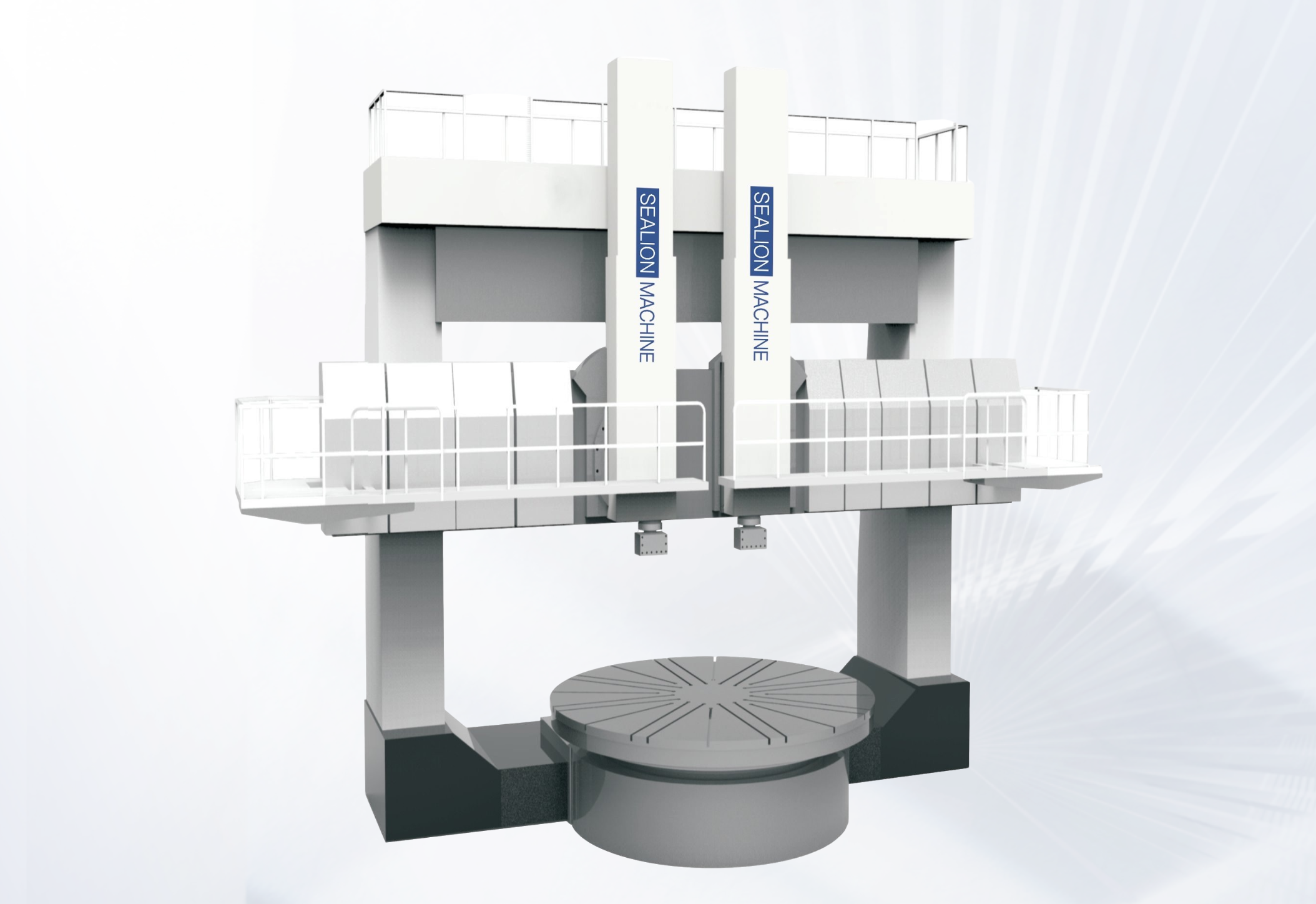

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES