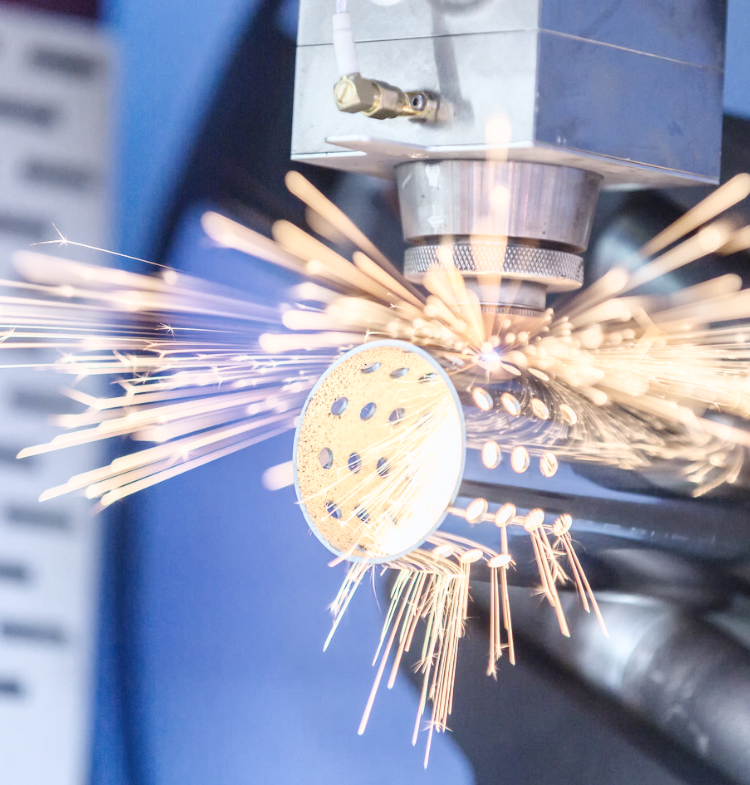

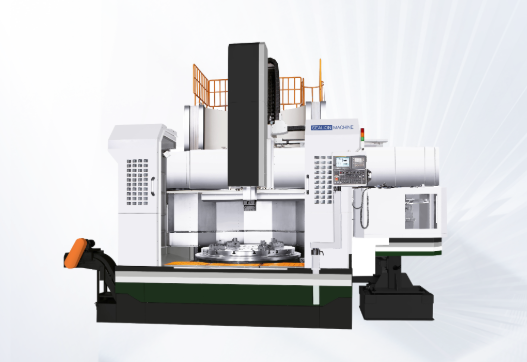

Vertical machining centers are mainly used for processing plates, discs, shells, molds and other high-precision, multi-pro cess, complex shape parts.

It can continuously complete milling, drilling, expanding, reaming, boring, tapping, and 2D-3D surface and beveled surface precision machining in one clamping, and the machining is programmed to shorten the production cycle, so that the user can get good economic benefits.

VMC series vertical machining center is one of the products developed by our company with independent intellectual property rights.

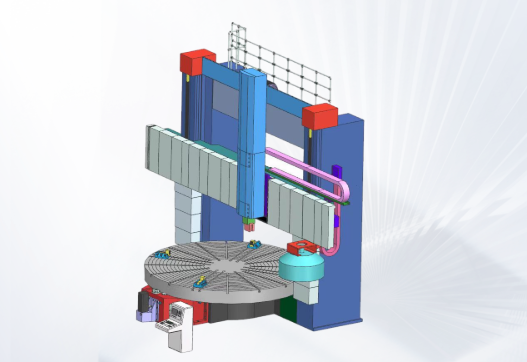

The machine tool adopts electromechanical integration structure and applies three-dimensional design software (UG) and finite element analysis software (Ansys) to carry out optimized design, which makes the machine tool structure design more reasonable, and the machine tool rigidity, precision retention, and reliability tend to be perfect.

Through the introduction of advanced design concepts, scientific design means, to solve the traditional design can not avoid the shortcomings.

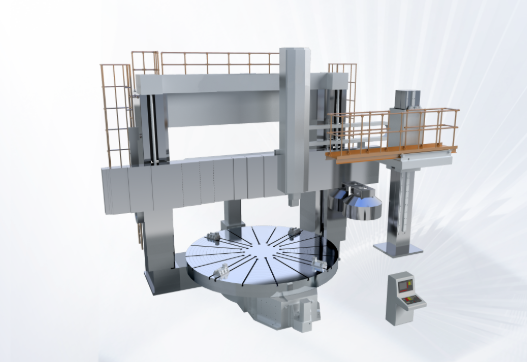

VMC series vertical machining center adopts vertical frame layout, the column is fixed on the bed, the spindle box moves up and down along the column (Z-direction), the slide moves longitudinally along the bed (Y-direction), and the table moves transversely along the slide (X-direction).

The bed, table, slide, column, spindle box and other large parts are made of high-strength cast iron, molding resin sand process, two times aging treatment to eliminate stress.

These large parts are optimized by UG and Ansys to improve the rigidity and stability of the large parts and the whole machine, effectively suppressing the deformation and vibration of the machine tool caused by the cutting force.

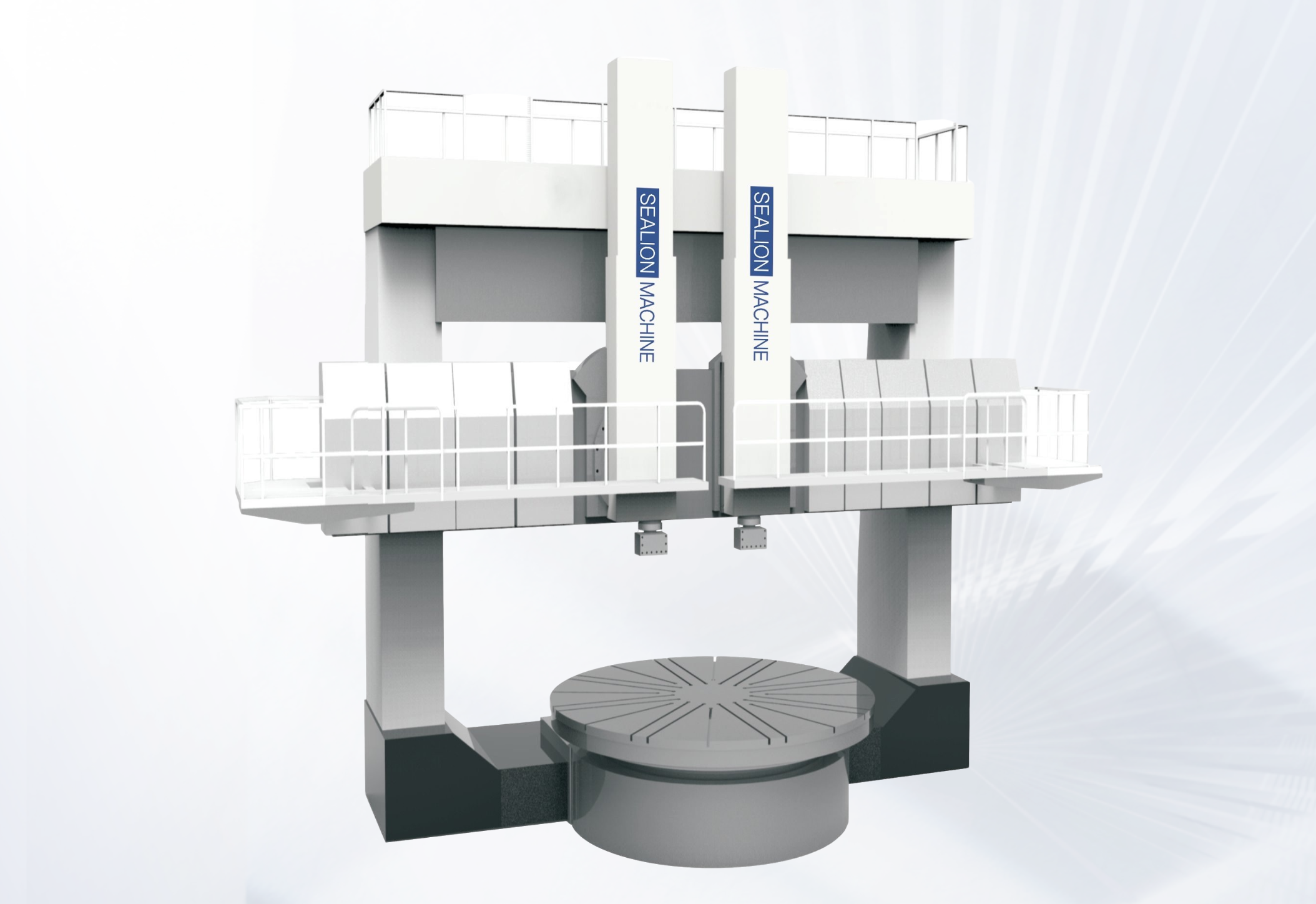

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES