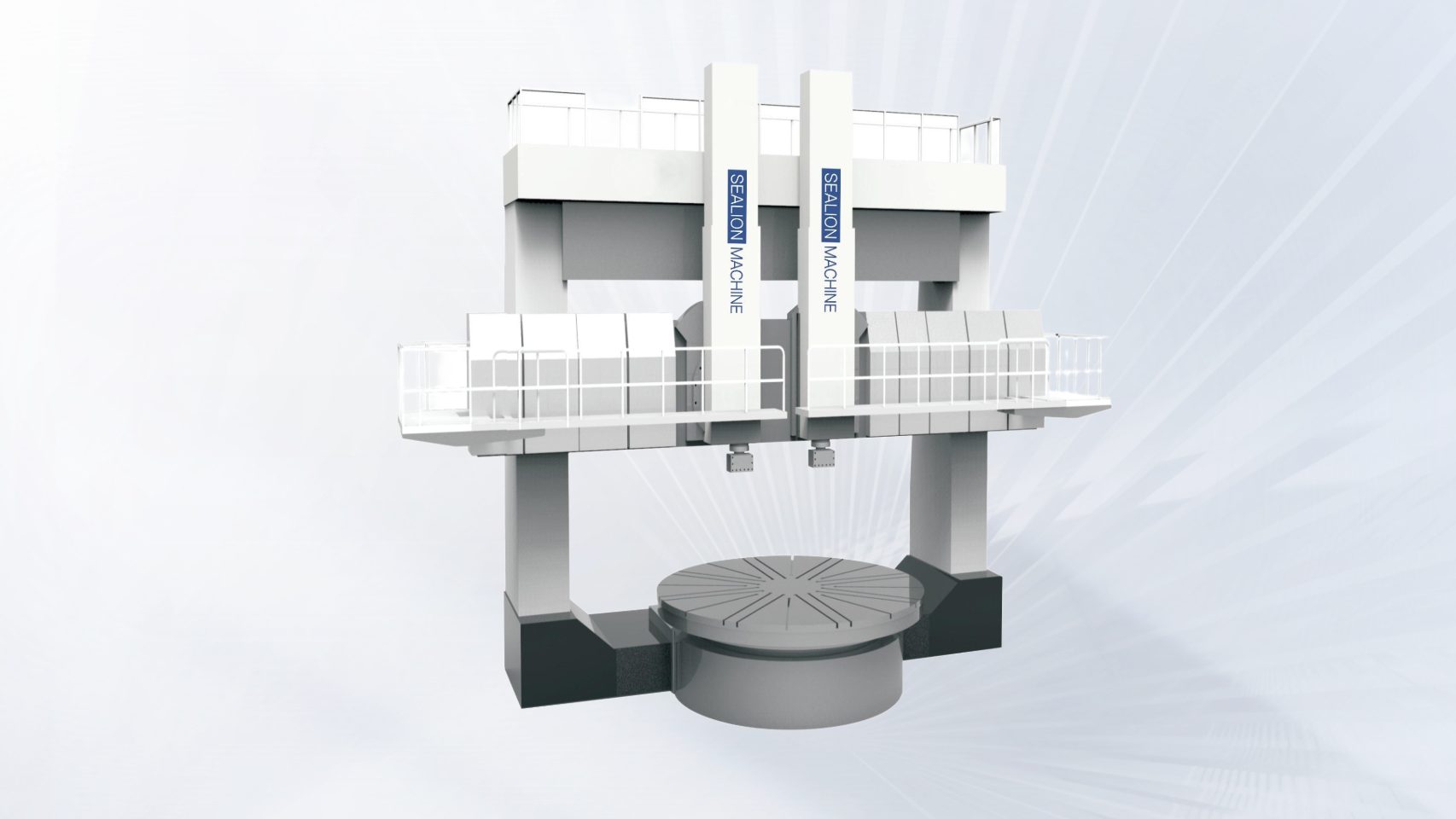

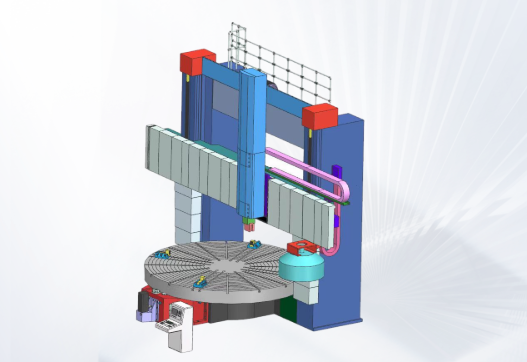

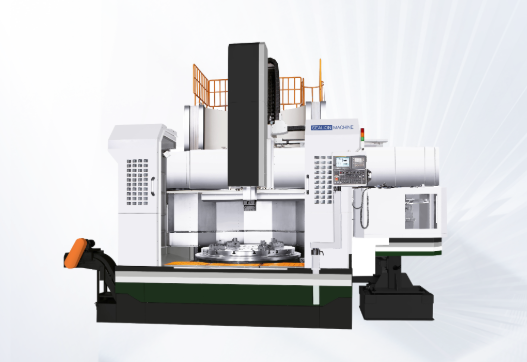

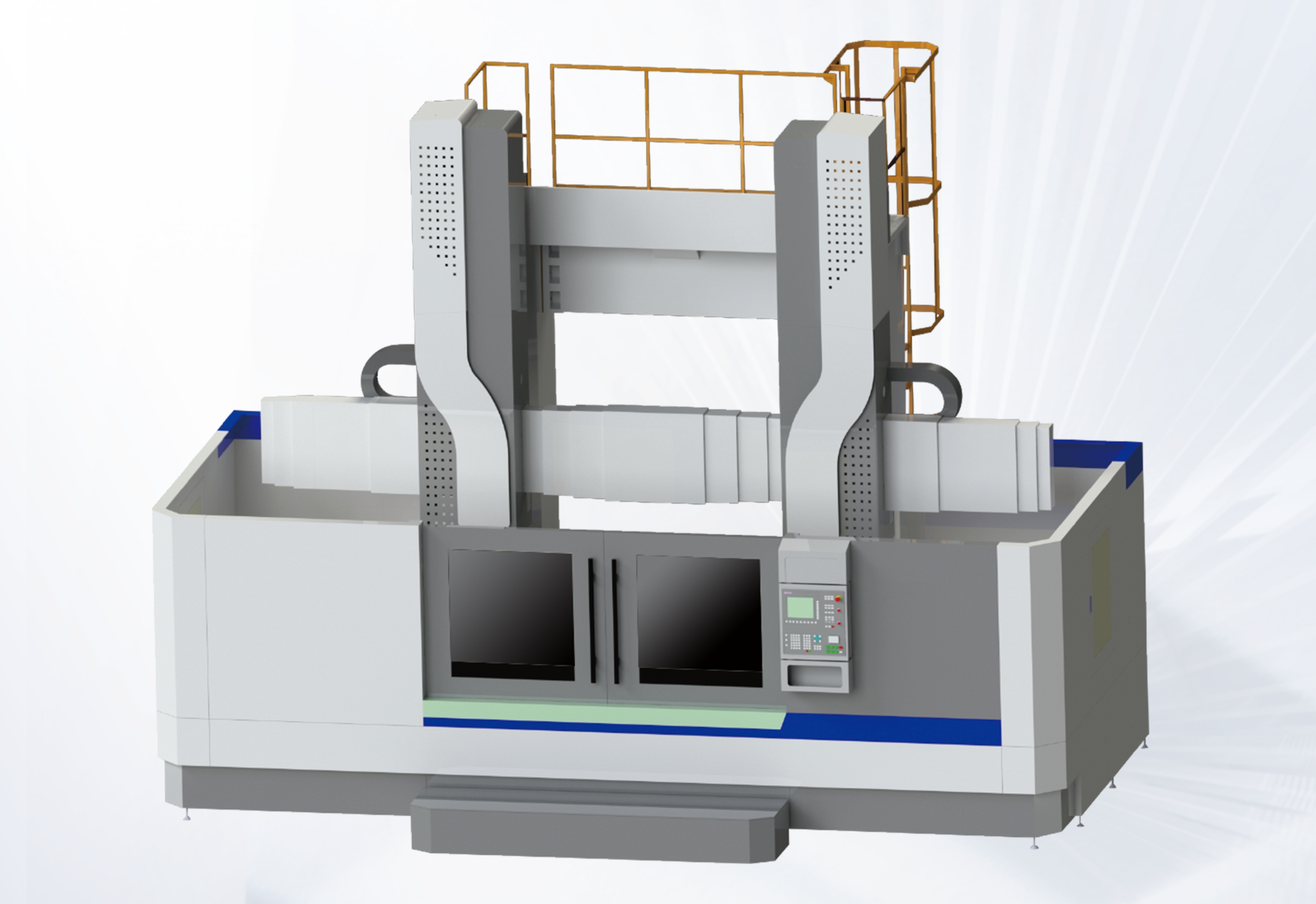

This series machine is upgraded from CK52D series.

The table and table base are cast in one piece with thermo-symmetric mechanism. The table adopts short spindle structure and is equipped with a set of NN3000K double-row short cylindrical roller bearings on the spindle, the inner ring of which is with 1:12 taper, which can be adjusted to ensure the high precision rotary of the table by adjusting the clearance of the bearings, and it has a long working life.

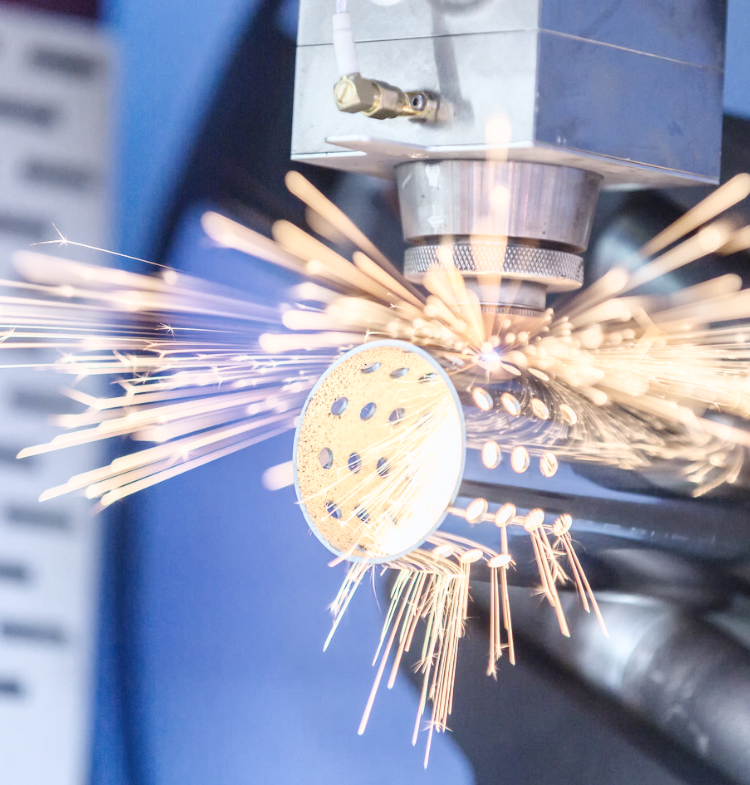

The flat circular guideway of the working table adopts constant flow hydrostatic composite guideway, and the pressure oil is injected into the oil cavity by the high-precision equal oil volume gear oil distributor, which ensures that the required oil film thickness and axial runout precision are achieved under the load of the working table. Thrust bearings with preload are installed on the spindle. To ensure the oil film stiffness and small end runout of hydrostatic guideway.

The main drive of the machine is driven by a vertical AC servo motor, which in turn passes through a vertical two-speed gearbox. The gearbox adopts helical gear transmission, and the gears are hardened and grinded to obtain high transmission accuracy and efficiency, and reduce transmission vibration and noise.

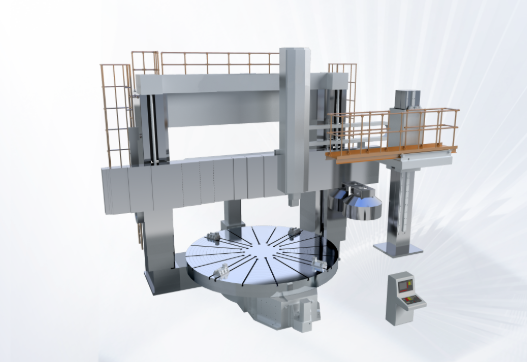

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES