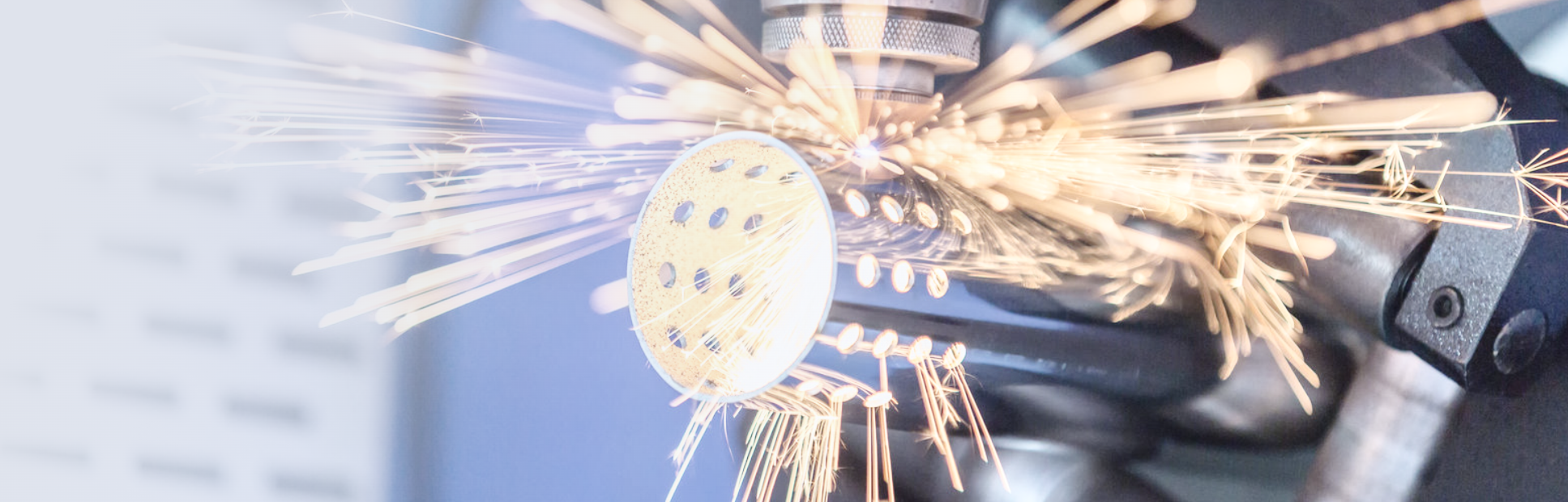

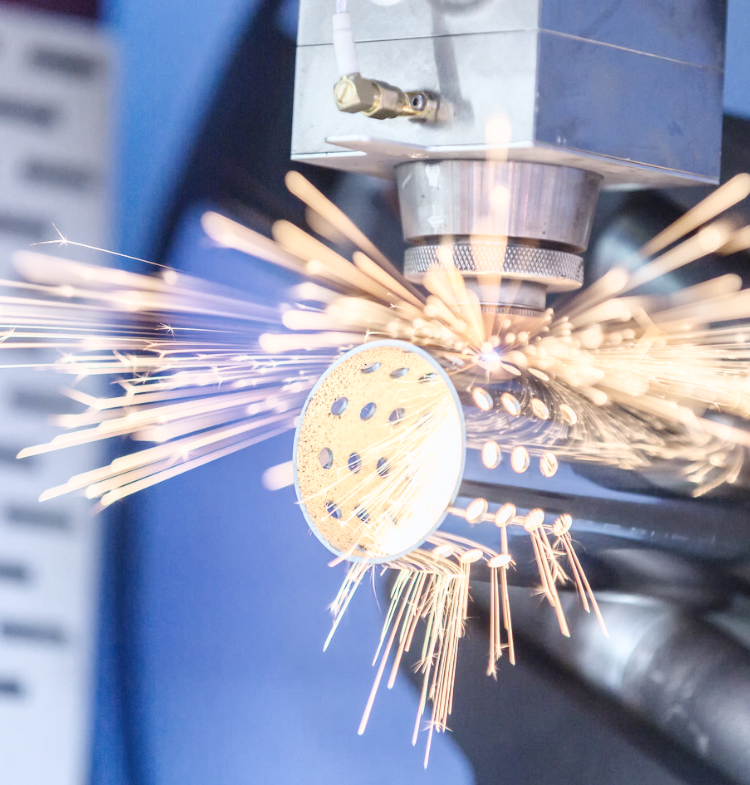

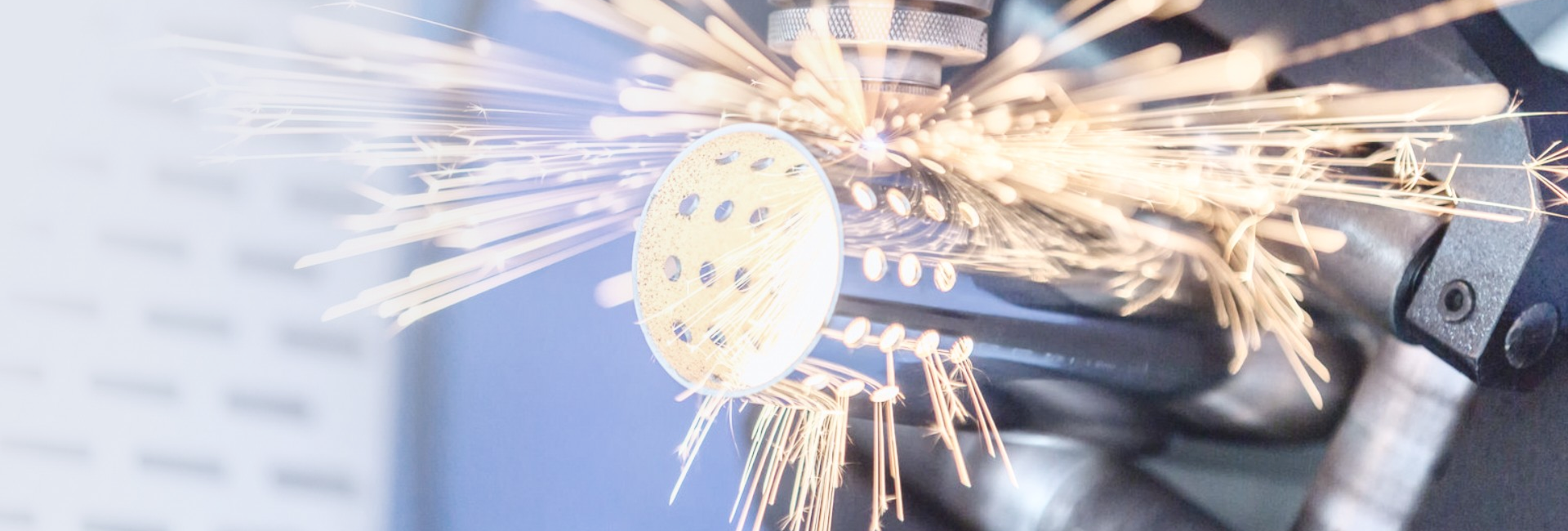

This series of CNC vertical lathes is an advanced equipment with excellent performance, wide process range, and high production efficiency. On the basis of drawing on advanced machine tool design and manufacturing, adopting the latest design concepts, combined with years of production and manufacturing experience of the enterprise. A series of precision machining equipment that integrates mechanical, electrical and hydraylic processes. This product is mainly suitable for high-speed steel, hard alloy cutting tools, and ceramic cutting tools, for rough and precision turning of inner and outer cylindrical surfaces, inner and outer conical surfaces, threads and circular arc surfaces of black metals, non-ferrous metals, and some non-metallic parts.

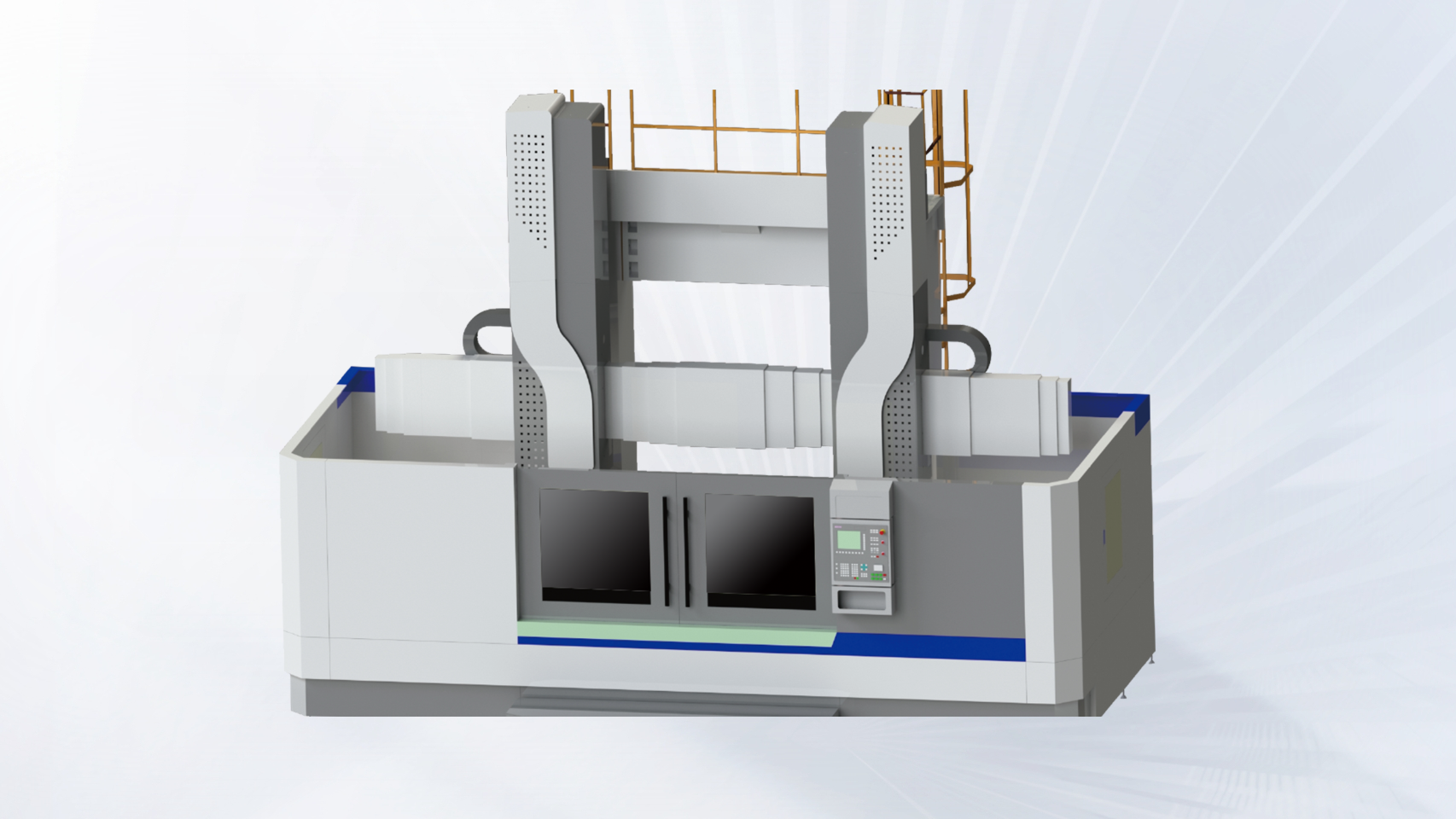

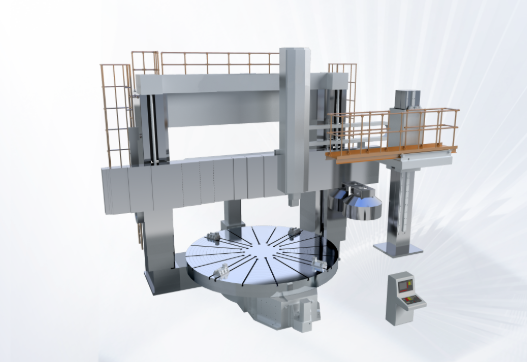

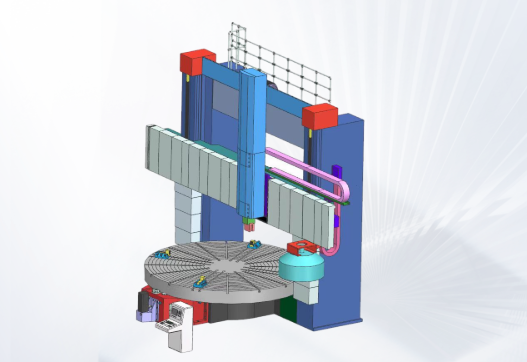

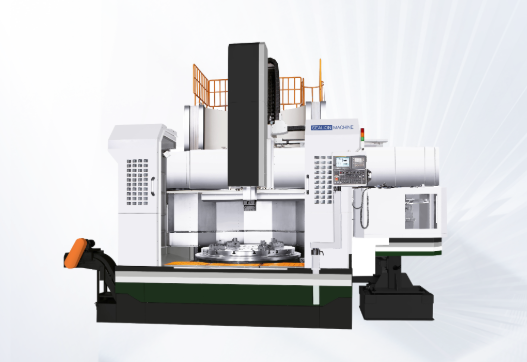

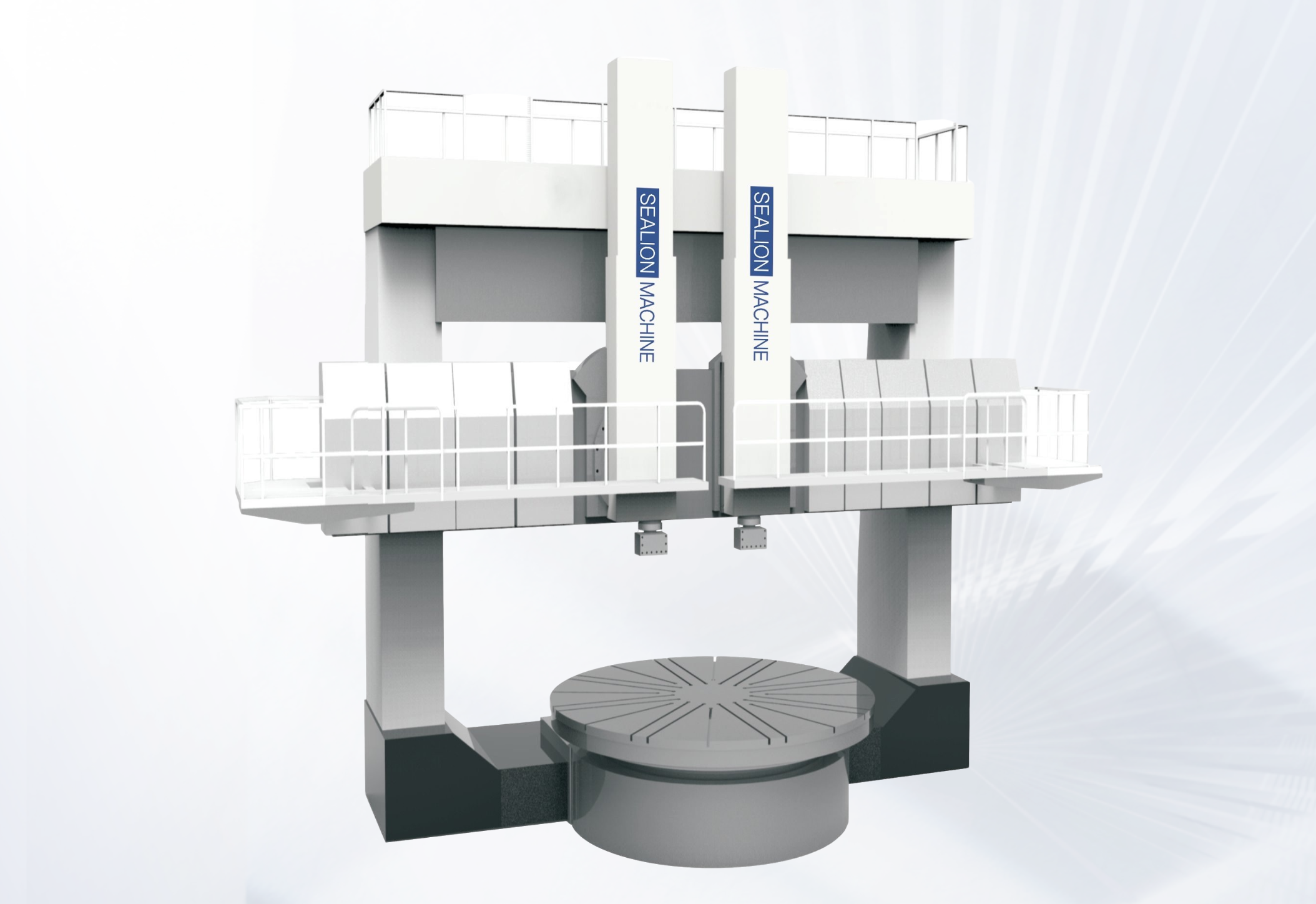

The column adopts a closed structure of gantry frame, and through finite element analysis calculation.

A long spindle structure is fitted on these sereis of machines. Two sets of NN3000K double row cylindrical roller bearings are assembled under the table. The table guideway adopts dynamic pressure guide rail or hydrostatic guideway, ensuring that the machine tool has high rotary accuracy and sufficient rigidity, strength, and thermal stability.

The horizontal guideway of the tool post using unloading guideway. sliding guideway or constant hydrostatic guideway and the vertical movement adopts sliding guideway.

The main transmission adopts a horizontal gearbox, which achieves the speed range of the worktable through a two speed, four speed, or 16 speed transmission mechanism.

Various options for your selection, closed-loop control, grinding function, internal tool setting device, coolant device and other functional components can be provided.

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES