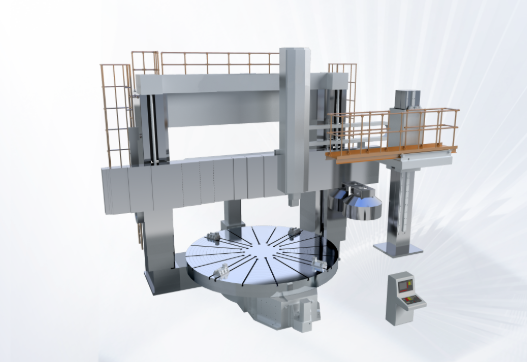

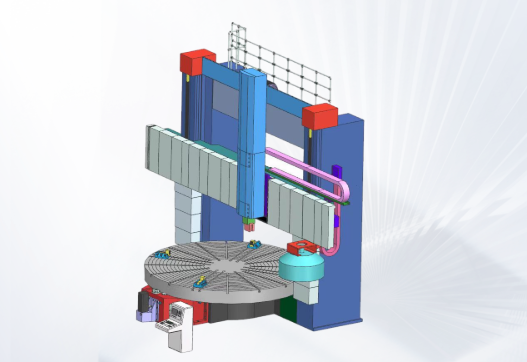

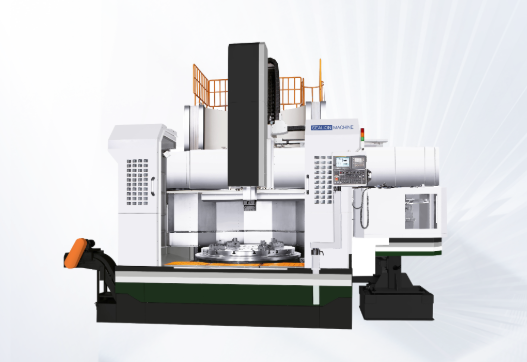

This compact-design machine features a more rigid structure with ergonomic engineering to minimize floor space while enhancing operator comfort.

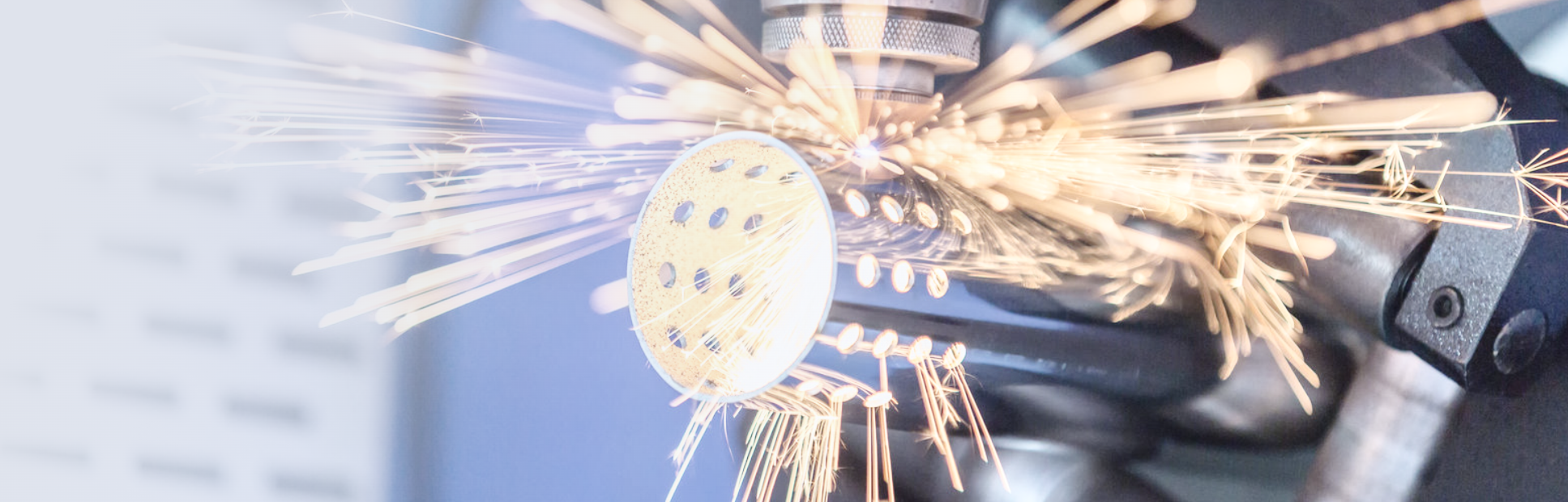

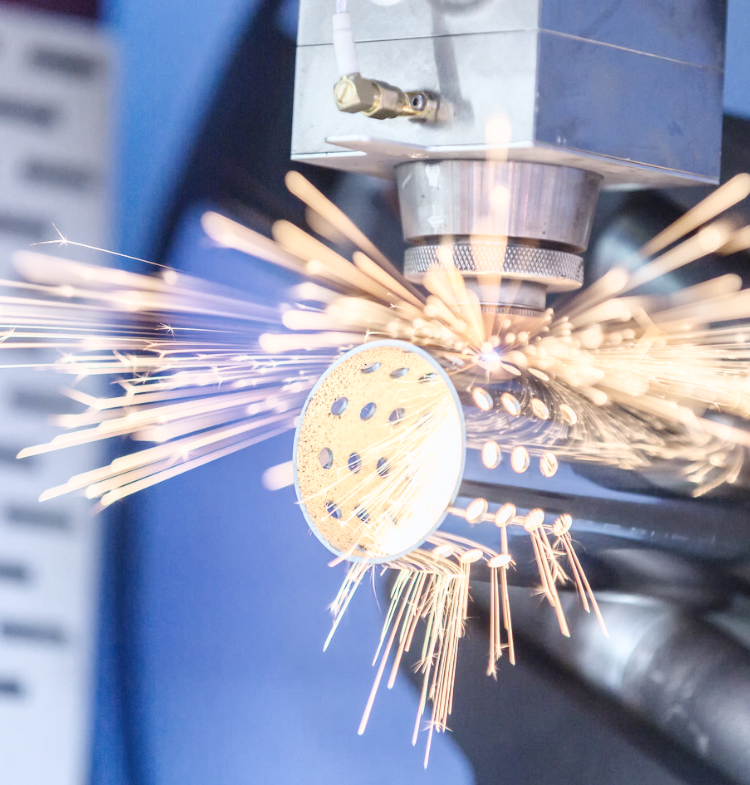

Its high-accuracy spindle system integrates advanced thermal control, a motorized spindle with high torque output, ensuring consistent precision and machining stability.

Built with world-class components like THK guideways, THK ballscrews, a NACHI hydraulic station, and an autogrip chuck, the system delivers reliable performance and durability.

To maximize versatility, optional configurations include a programmable tailstock, sub-spindle, tool presetter, and workpiece measurement systems, enabling efficient setup, complex part processing, and quality control in a single integrated solution.

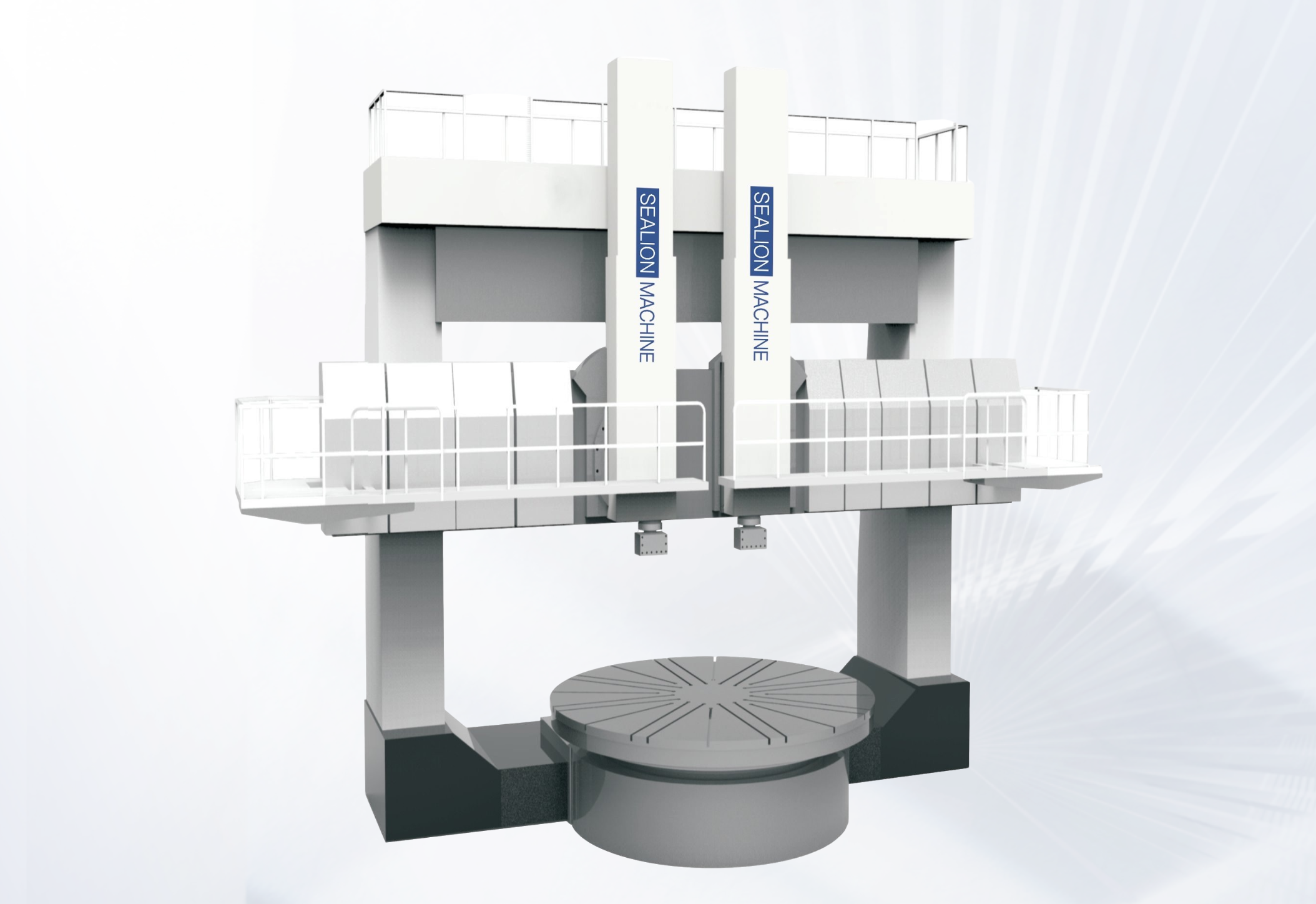

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES