Cutting Performance

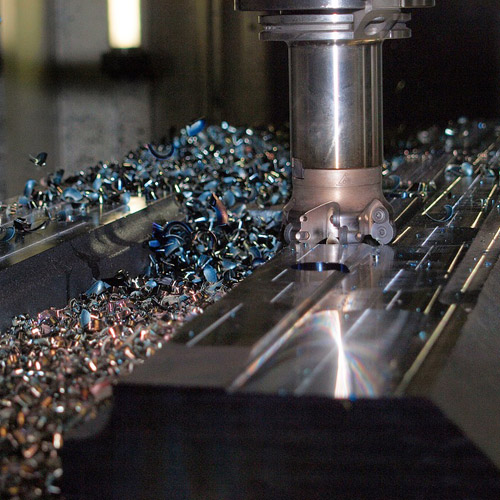

CUTTING-EDGE TECH LEADS TO ENHANCED CUTTING PERFORMANCE

The demands placed on your business become tougher every day, as modern manufacturers are tasked with meeting ever-tightening tolerances, and problem-solving to deliver the desired result by strict deadlines. At Okuma, we’ve developed Intelligent and Advanced Technologies for the sake of lending a helping—and a very innovative—hand. Each technology, in its own way, was designed to enhance machine cutting performance, no matter how complicated the part shape, no matter how complex the part surface. Every manufactured part is unique. And now, you have the tools to ensure speed, accuracy, and efficiency when you face your next manufacturing challenge.

machine of technology

-

Hydrostatic Rotary TableWe use hydrostatic rotary table for the big vertical lathe, which provides a better performance and high accuracy.

-

Thermo FriendlySave time, which improves overall productivity. Save money through reduced energy usage and labor (time) costs

-

DVT ModeSEALION modify the conventional machine to be DVT mode. A servo motor will drive the Ballscrew through a gearbox, which provide the best performance, high accuracy, convenient after service.

-

Operator ProductivityWith support from main CNC machine tools suppliers, you’re making a smart investment for the person who’ll be using that machine.

-

Cutting PerformanceCutting-edge tech leads to enhanced cutting performance.

-

EnergyEnergySEALION has good experience in the development of specific but cheap machine tools that ensures precision and quality required in the energy sector.

-

Earth MovingEarth MovingAt present, the construction machinery industry has a considerable scale, which can produce more than 3000 varieties of quality machine tools in 18 categories.

-

Die&MoldDie&MoldQuality machine tools can do machining from raw blocks, machining in roughing and fine finishing, machining all kinds of molds and mold-holders in both vertical or horizontal positions.

-

General MachiningGeneral MachiningWe offer a wide range of quality machine tools for your general machining and fabrication work in your factory.

-

EnginesEnginesSEALION has a wealth of experience in the field of the motor for more than twenty years.