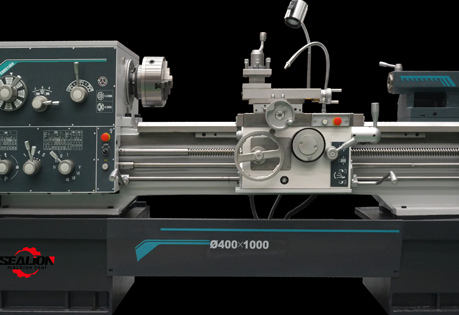

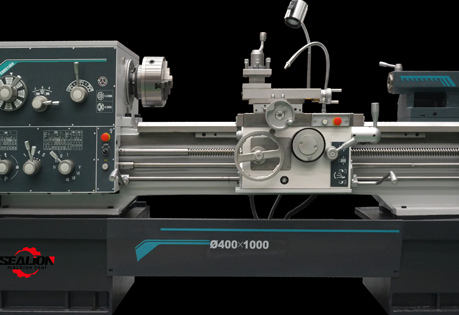

Conventional Lathe

Conventional Lathe is perfectly suitable for small volume production plant and machinery maintenance shops and can machine a wide range of materials.

Features of Conventional Lathe

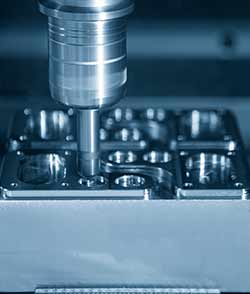

The machine is a one-piece casting because the bed is cast as a whole, the guide rail of the bed adopts the layout of mountain and plane guide rail, which has a large bearing section, so it has good rigidity and vibration absorption, which can ensure high-precision machining.

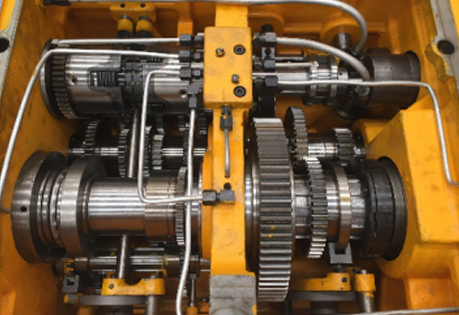

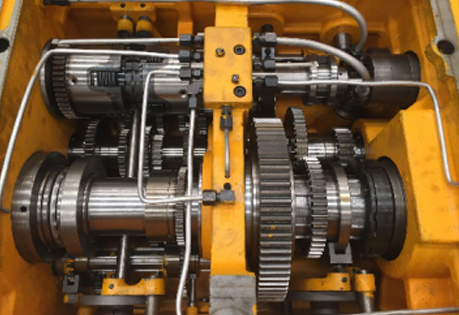

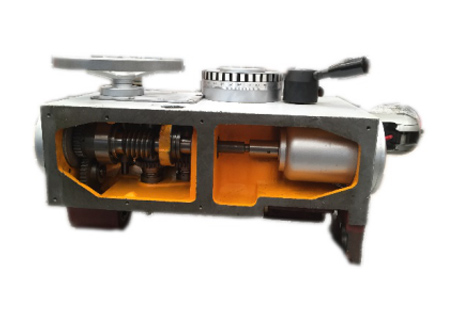

The machine tool adopts the mechanical friction plate clutch to realize the speed change, stop and change of the spindle without changing the speed of the motor and stopping the main motor.

It can turn the outer circle, inner hole, end face, drill hole, ream hole, and pull oil groove.

Nn3020k series double row cylindrical roller bearing is used at the front end of the main shaft, 7214ac angular contact ball bearing and 51215 series axial thrust ball bearing are used at the rear end, and appropriate preload is applied, matching with the best span support and box-type main shaft box so that the main shaft has high rigidity.

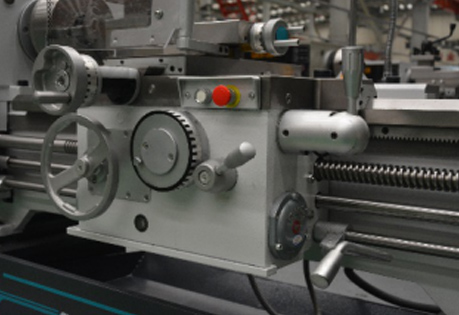

The slide box of the machine tool is equipped with a fast-moving device, which can quickly move to the required position in the vertical and horizontal directions. It has the interlock protection function of the light screw and the lead screw to ensure the normal and trouble-free operation of the feeding system.

The machine tool is equipped with a belt cover and a safety warning sign to prevent the operator of the machine tool from being injured and the equipment from being damaged. According to the user's needs, it can also provide chuck protection, tool holder protection and full protection to ensure your safe operation.

In order to ensure the site is clean, there is a chip receiving tray at the lower part of the bed to ensure that the chips are far away from the processing area. An Independent cooling system is equipped with a large flow cooling pump to provide forced cooling for turning.

Advantages of Conventional Lathe

This series compact conventional lathes can perform a variety of turning applications, for example: turning internal and external cylindrical surfaces, end face and a conical surface, gap lathe is used to cut larger diameter or irregular sharped parts. Metric or imperial leadscrew lathe is available to produce metric, inch, module, and diametral pitches upon customer’s request, and also accomplish drilling, reaming and oil grooving.

High rigidity mechanical tool holder, with high reliability and high repeated positioning accuracy.

The slide box of the conventional lathe machine tool is equipped with a fast-moving device, which can quickly move to the required position in the vertical and horizontal directions.

Conventional lathe machine operation: It has the interlock protection function of the light screw and the lead screw to ensure that the feeding system can work normally without failure.

The feed box of the machine tool can change the type of thread by changing the handle position of the feed box.

The slide box of the machine tool is equipped with the fast-moving device, overload safety protection device, and vertical and horizontal cross operation, Longitudinal handle, opening, and closing nut handle.

Various safety and protection accessories available for users.

Conventional Lathe Machine Specification

| Model No | Unit | C6140 | C6150 | C6156 | C6166 |

| Max swing over bed | mm | 400 | 500 | 560 | 660 |

| Max swing over the cross rail | mm | 230 | 290 | 350 | 440 |

| Max Length of Job | mm | 750/1000/1500/2000/3000 | |||

| Width over bed ways | mm | 394 | |||

| Spindle bore diameter | mm | D8 82 | |||

| Chuck Size | mm | 250 | 350 | ||

| Taper of spindle | 90mm 1:20 | ||||

| Max Spindle Torque | Nm | 1100 | |||

| Spindle speed range | rpm | 26-2000(16 steps) | |||

| Spindle center height | mm | 220 | 250 | 280 | 325 |

| Spindle motor power | KW | 7.5(10HP) | |||

| Tailstock quill diameter | mm | 75 | |||

| Tailstock quill travel | mm | 150 | |||

| Tailstock quill taper | No 5 MT | ||||

| Longitudinal feeding speed | mm/rpm | 0.044~1.48(45 Steps) | |||

| Cross feeding speed | mm/rpm | 0.022~0.74(45 Steps) | |||

| Tool Post | mm | 25x25 | |||

| Machine Weight | Kg | 2070 | 2120 | 2180 | 2400 |

Configuration List of Conventional Lathe

Standard Configuration

3-Jaw Chuck

Center used in tailstock

Foot Brake

Steady Rest

Following Rest

Lead Screw Cover

4-way tool post

Standard Tool Kit

Optional Configuration

4-Jaw Chunk

Chunk Guard

Tool post guard

Rear splash guard

Face plate

Drive plate

DRO

Leveling pad

Spindle center and center sleeve

Live center

Thread dial

Taper-turning attachment

Vertical hard stop

Anchor bolt