Vertical Lathe

Sealion Machine Tool supplies a wide range of vertical lathe machine -- single column vertical lathe, 2-axis CNC single column vertical lathe, double column vertical lathe and 2-axis CNC double column vertical lathe. We have been selling vertical lathe for years and have made great reputation as a cnc vertical milling machine manufacturers. We keep a high-level quality standard of our lathe machines. Those kinds of vertical lathes for sale are suitable for general machining work, such as turning, milling, threading, drilling, etc. All kinds of accessories are also available for different machines. CNC vertical lathe machine is widely used in metallurgy, chemical industries, mining, energy, shipping, and military industries. Our products are available in vertical lathe turning, vertical lathe drilling, vertical lathe threading and vertical lathe milling. Come and inquiry Sealion vertical turning lathe and vertical turret lathe machine.

-

The machine is suitable for rough or fine machining of auto, bearing, wind power, motor, and water pump, etc. The base and column use one-piece high-quality castings. X&Z is using a brand linear guideway. The main transmission is driven by frequency or a servo motor, simple structure, and high transmission efficiency.

The machine is suitable for rough or fine machining of auto, bearing, wind power, motor, and water pump, etc. The base and column use one-piece high-quality castings. X&Z is using a brand linear guideway. The main transmission is driven by frequency or a servo motor, simple structure, and high transmission efficiency. -

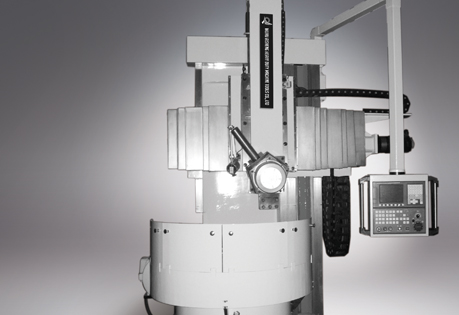

2-axis CNC vertical lathe is the machine based on the conventional VTL, The base and column use one-piece high-quality castings. The machine is suitable for rough or fine machining of auto, bearing, wind power, motor and water pump, etc.

2-axis CNC vertical lathe is the machine based on the conventional VTL, The base and column use one-piece high-quality castings. The machine is suitable for rough or fine machining of auto, bearing, wind power, motor and water pump, etc. -

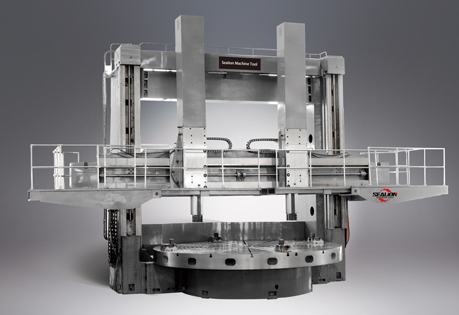

Double column vertical lathes are designed with hydrostatic bearings for better cutting performance. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements. The machine is designed for heavy and big size job.

Double column vertical lathes are designed with hydrostatic bearings for better cutting performance. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements. The machine is designed for heavy and big size job. -

Double column vertical lathe is designed with hydrostatic bearings for better cutting performance. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements.

Double column vertical lathe is designed with hydrostatic bearings for better cutting performance. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements.

Pay Attention to the Operation Process of Vertical Lathe

1. The rough surface of the workpiece is not allowed to be directly placed on the work surface, and should be supported by a shim or screw top; it is strictly forbidden to use the work surface for other operations such as hammering to correct the workpiece, welding the workpiece, and so on.

2. When aligning the workpiece, only jog the worktable at low speed to align it, and high-speed aligning is not allowed.

3. When starting and stopping the workbench, the start and stop handle of the workbench can only be moved by hand, and pedaling is strictly prohibited.

4. When the worktable is rotating, it is not allowed to do the lifting of the beam and the rapid movement of the tool post.

5. When moving the beam, the clamping device must be released first, and the clamping device should be clamped immediately after the movement. Each time the beam is lowered, it should rise a little to eliminate the gap between the lead screw and the nut.

6. Gravity cutting processing is not allowed when the ram of the vertical tool rest and the side tool rest is extended for a long time; the vertical tool rest is used for processing, especially for gravity cutting, the beam should be lowered as close to the work as possible Location.

7. When doing intermittent cutting, the feed amount and table speed should be appropriately reduced.

8. The joystick must be pushed to the specified position when shifting. If the gear is not meshed well, it should be adjusted by fine movement after work, and no forced operation is allowed.

Maintenance of Vertical Lathe

1. Strictly abide by the operating procedures and daily maintenance system when using cnc vertical milling machine.

2. Prevent dust from entering the electronic control device. Floating dust and metal powder can easily cause the insulation resistance between electrical components to decrease, resulting in failure or even damage to the components of the vertical CNC machines.

3. Clean the heat dissipation and ventilation system of the electric control cabinet regularly.

Vertical Lathe VS Horizontal Lathe

Vertical and horizontal lathes consist of the same components, and there is only one real difference between the two. Vertical lathes are essentially horizontal lathes designed to be placed upright. If there is limited space in the workshop, or some people prefer certain mechanics, they will choose a vertical lathe. When using a vertical lathe, the mechanic must move up and down.

In contrast, when using a horizontal lathe machine, the machinist processes the metal in a side-by-side manner. Both types of lathes can enable machinists to make similar products. Generally, those who have experience using lathes like to stick to the most comfortable thing.

-

SEALION has good experience in the development of specific but cheap machine tools that ensures precision and quality required in the energy sector.

SEALION has good experience in the development of specific but cheap machine tools that ensures precision and quality required in the energy sector.

-

At present, the construction machinery industry has a considerable scale, which can produce more than 3000 varieties of quality machine tools in 18 categories.

At present, the construction machinery industry has a considerable scale, which can produce more than 3000 varieties of quality machine tools in 18 categories.

-

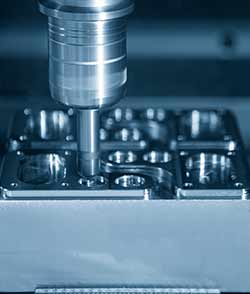

Quality machine tools can do machining from raw blocks, machining in roughing and fine finishing, machining all kinds of molds and mold-holders in both vertical or horizontal positions.

Quality machine tools can do machining from raw blocks, machining in roughing and fine finishing, machining all kinds of molds and mold-holders in both vertical or horizontal positions.

-

We offer a wide range of quality machine tools for your general machining and fabrication work in your factory.

We offer a wide range of quality machine tools for your general machining and fabrication work in your factory.

-

SEALION has a wealth of experience in the field of the motor for more than twenty years.

SEALION has a wealth of experience in the field of the motor for more than twenty years.