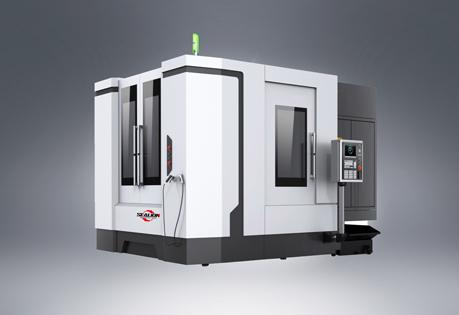

Gantry Machining Center

SEALION supplies Gantry Machining Center both tables moving type or gantry moving type. Gantry type machining center is widely used in the aviation, auto, precision molding industries. It provides a high-performance mechanical system and a software interface which can be operated easily.

The gantry structure of the Gantry Type Vertical Machining Center provides greater rigidity and stability compared to other types of machines, making it capable of handling heavier and larger workpieces. The fixed table also makes it easier to set up and secure the workpiece, while the gantry's movement provides greater flexibility in machining complex shapes and contours.

Features of Gantry Machining Center

Adaptability

Gantry machining center has always been a classic and practical machining center series. Since its debut in the industry, it is a highly developed machine. It can handle many heavy-duty precision machining tasks on large and hard workpieces without the need to immediately transfer the machined workpieces to other milling centers during the machining process. In the early days of the slow development of the machinery industry, the machine tool center was developed from the milling machine in the middle of the last century. Since then, the progress of the gantry machining center has been very smooth, and the gantry CNC machining center has been widely used in various industries. Because of its strong adaptability, it has made great contributions to the world's industry.

Swift and Smart

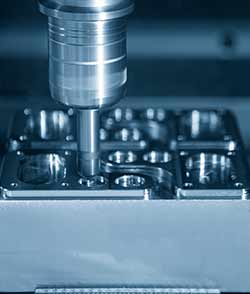

In fact, the gantry CNC machining center is more like an advanced milling machine with excellent functions. The milling process of the gantry CNC machining center is a process in which a rotating tool is used to push the tool into one or more workpieces to remove the workpiece material, just like an ordinary milling machine. At the same time, this processing method can be completed in different directions. Generally speaking, an ordinary machining center installs at least three shafts as its basic components on the basic components.

In addition to turning, milling on gantry CNC machines also covers a wide range of operations, from single small parts to heavy and large milling operations. Similar to turning, milling is one of the most commonly used machining methods, which can achieve precise tolerances within precise requirements. In other words, the application and practicability of machining centers stimulated the development of milling methods, and later became very popular in industries that require strict machining accuracy.

Gantry Machining Center Working Principle

Range of Milling Tools

Gantry machining center provides processing equipment for different levels of creation. This example includes CNC machining operations, light duty and overwhelming duty.

The spindle is set to open the hole vertically during vertical milling. Among them, the axle is still the fundamental determining factor.

Only with the aid of the axle, the machine can be balanced on all sides of the workpiece material,

The gantry machining center type especially provides CNC machining and VMC. The examples include: WM array vertical CNC machining machine and WM array gantry type processing concentrated in a few design companies.

The shaft characteristics of the gantry milling device

Accessible gantry machining equipment outlines the latest machine planning process to request programming assistance. The processing equipment can be accessed through 5 opposing processing axes. This face-to-face machining reduces the introduction of workpiece metal. Therefore, this machine is multifunctional and can be operated physically and naturally.

X-axis and Y-axis mechanism in gantry milling

The X-hub, Y-hub and Z-pivot axes separate the 5 facing machining axes. The X hub axle can be customized with manual assistance. In addition, Y-hub is tested in programming mode. The Z axis is still helpful for processing metal workpieces with larger widths. The Y-shaped hub and Z-shaped pivot enhance the accuracy of machining operations.

Advantages of Gantry Type Vertical Machining Center

Gantry type vertical machining centers, also known as CNC gantry type machining centers, are highly advanced machines used in modern manufacturing industries. These machines have several advantages over traditional machining centers, making them an essential tool for high-precision machining applications.

Large Work Envelope

One of the primary advantages of gantry machining centers is their large work envelope, which allows them to machine large and heavy workpieces. This makes them an ideal solution for industries such as aerospace and automotive, where complex and large parts need to be machined with precision.

High Precision and Accuracy

Another key advantage of gantry type machining centers is their high precision and accuracy. These machines are built with rigid constructions and high-quality components, ensuring that they can withstand high cutting forces while maintaining their accuracy over extended periods of operation. This feature makes them an ideal choice for industries that require highly precise and accurate machined parts.

High Production Capacity

Gantry type machining centers also offer high production capacity, thanks to their high spindle speeds and rapid traverse rates. These features allow for faster material removal rates, reducing cycle times and increasing productivity. Additionally, these machines can be equipped with automation systems such as robots and pallet changers, allowing them to run unattended for extended periods of time.