Floor Type Boring Mill

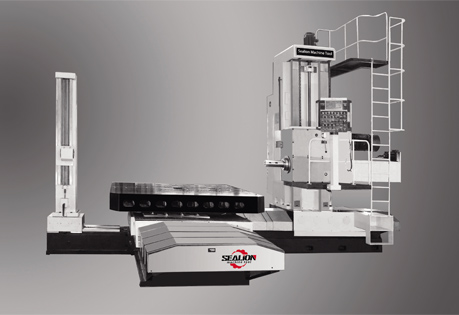

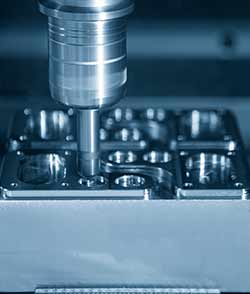

Floor Type Boring Mill is suitable for large size jobs to do milling, boring, drilling, etc. The floor type boring and milling machine is widely used in energy, shipbuilding, mining, nuclear power, etc.

Sealion Machine Tool is an experienced floor type boring milling machine manufacturer and supplier based in China. With years of experience in the industry, Sealion has gained a reputation for producing high-quality and reliable CNC floor boring machines that meet the needs of various industrial applications. Sealion has high-quality floor boring machine for sale. Don't hesitate to contact us, if you are in need.

Sealion Floor boring machine for sale, contact us for more info!

Advantages of Floor Type Horizontal Boring Machine

1. X-axis travel is more than 16 meters, Y-axis travel is 5 meters, and the capacity is large.

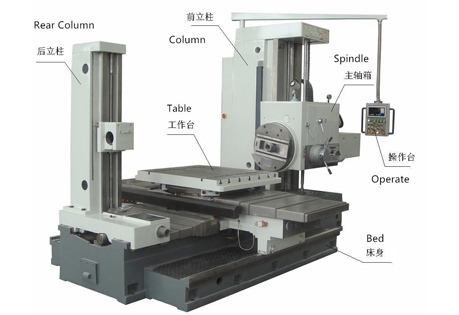

2. Modular design-select machine features and functions according to the application. Choose from five types of headstocks-two-speed or four-speed, with a spindle diameter ranging from 130 to 180 mm.

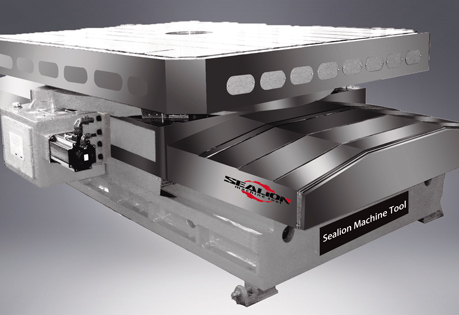

3. The design maximizes stiffness through a wide extension, reinforced column, and preloaded rack and pinion X-axis drive.

4. Use the optional horizontal/vertical tool changer arm to replace the tools and accessories in the standard live spindle and right-angle tool head from the tool magazine.

Parameters of Floor Type Boring Mill

| Model No | Unit | TK6213 | TK6913 | TK6216 | TK6916 | TK6920 |

| Boring Spindle Diameter | mm | 130 | 130 | 160 | 160 | 200 |

| Milling Spindle Diameter | mm | 221.44 | 221.44 | 260 | 260 | 340 |

| Spindle Taper | ISO50 | ISO50 | ISO50 | ISO60 | ISO60 | |

| Spindle Speed | r/min | 3-700 | 3-700 | 3-1000 | 3-1500 | 3-1500 |

| Max Torque of Spindle | N.m | 4,000 | 4,000 | 5,000 | 7,000 | 11,000 |

| Power of Main Motor | Kw | 22 | 22 | 37 | 71 | 75 |

| Ram Size | mm | / | 350x420 | / | 480x520 | 480x520 |

| Column Travel X | M | 4/6/8 | 4/6/8 | 4/6/8 | 6/8/10/12 | 6/8/10/12 |

| Vertical Travel Y | M | 2/2.5 | 2/2.5 | 2/3 | 2/3/4 | 2/3/4/5 |

| Travel of Spindle Z | mm | 1,000 | 700 | 1,000 | 1,200 | 1,200 |

| Ram Travel W | mm | / | 700 | / | 1,200 | 1,200 |

| Feeding Speed X | mm/min | 4-3,000 | 4-3,000 | 4-3,000 | 0.5-6,000 | 0.5-6,000 |

| Y | mm/min | 2-3000 | 2-3000 | 2-3000 | 0.5-6,000 | 0.5-6,000 |

| Z | mm/min | 1-2000 | 1-2000 | 1-2000 | 0.5-5,000 | 0.5-5,000 |

| W | mm/min | / | 1-2,000 | / | 0.5-4,000 | 0.5-4,000 |

| Positioning Accuracy X&Y | mm/1M | +/-0.02 | +/-0.02 | +/-0.03 | +/-0.03 | +/-0.03 |

| Z&W | mm/1M | +/-0.02 | +/-0.02 | +/-0.03 | +/-0.03 | +/-0.03 |

| Repeatability Accuracy | mm/1M | 0.035 | 0.035 | 0.035 | 0.035 | 0.035 |

| Machine Weight | Kg | 34,000 | 38,000 | 38,000 | 115,000 | 135,000 |

| Machine Size | M | 7.9x3.5x5.9 | 7.9x3.6x5.9 | 8.2x3.6x5.9 | 10x3.5x7.0 | 12.5x3.5x8.0 |