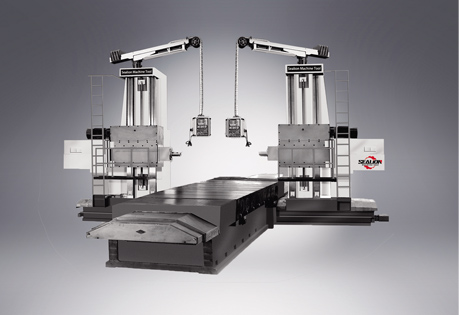

Rotary Table

DRO/CNC Rotary Table is a patented machine with our own design. Rotary Table casting is together with the oil recycle system, it makes the machine very clean and beautiful. SEALION supply cheap rotary tables from 10T up to 250T.

Features of Rotary Table

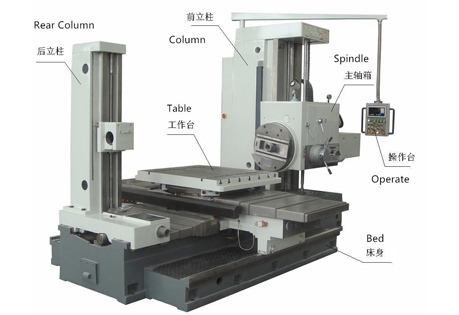

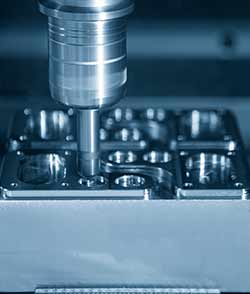

The rotary table is an accessory for the CNC floor type boring and milling machine. It can be working together with the floor type boring milling machine for milling angle, reverse boring, polyhedral machining, and other complex machining processes. It could do five sides machining if the main machine equipped the angle milling head.

Sealion supplies cheap rotary tables from 10T to 250T loading, both CNC and DRO type. It can be tailor-made for your own boring machine.

Application Scope of CNC Rotary Table

CNC rotary table is a common part of CNC milling machine, often used as a servo axis of CNC milling machine, namely C axis of vertical CNC milling machine and B axis of horizontal CNC milling machine. The CNC rotary table includes the foot of the turntable, a round turntable surface, four rolling bearing parts arranged on the upper surface of the foot of the turntable, and a center with a self-aligning bearing installed at the center of the upper surface of the foot of the turntable. Support, each rolling bearing component includes a rolling bearing and a support that supports the rolling bearing through the axle. The center of the lower surface of the turntable is provided with a vertical downward axle. The turntable is installed on the foot of the turntable. The inner ring of the self-aligning bearing is fixed, and the rotating surface of the rolling bearing is in rolling contact with the lower surface of the turntable surface.

The CNC rotary table has an inclinometer with two orthogonal test axes as the test tool. The inclinometer is set at the center of the turntable surface to be leveled, so that the two orthogonal test axes of the inclinometer are parallel to the turntable surface, by adjusting the milling machine turntable. The leveling mechanism under the base makes the tilt angle value output by the two test shafts of the inclinometer turntable in the leveling state.

CNC rotary table and swing head are the key components of multi-coordinate CNC machine tools. Traditional rotary tables and swing heads using high-precision worm gears and other transmissions are not only difficult to manufacture, costly, but also difficult to achieve the speed and accuracy required for high-speed machining. Therefore, it is necessary to develop a new electromagnetic drive system for the CNC milling machine turntable and swing head in a different way to realize the zero-drive drive of the rotational motion coordinates of the CNC machine tool.

Working Principle of Rotary Table

1. The CNC turntable uses modular design technology. The PAN turntable and TILT turntable are independent components, which are easy to disassemble and can be controlled by linkage or individually.

2. The use of AC servo motor drives the harmonic wave reducer transmission system to ensure that the equipment not only runs stably at low speeds, but also has fast dynamic response performance.

3. The automatic control system is composed of a PC and a motion controller based on DSP, which ensures the openness and convenience of expansion of the automatic control system.

4. The control software developer platform uses the Windows platform, which can make full use of various data visualization development tools, which greatly simplifies the progress of experimentation, research, and research and development.

Advantages of Rotary Table

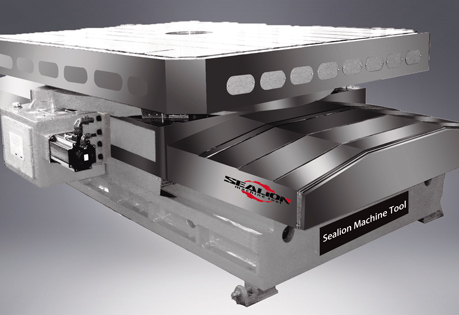

The rotary bearing of the table adopts double row cylindrical roller bearings and central unloader equipment which enhanced the accuracy of the table

The working table linear guideway is coated with plastic tapes and the rotary motion fitted with the compound guideway. It makes the machine better accuracy and easy maintenance.

The linear traveling system is composed of anti-backlash reducer and ballscrew. The rotary traveling system is driven by the servo motor and double pinion gearbox. Those features guarantee the best accuracy.

The linear scale is the standard for linear movement. The high accuracy rotary encoder is also optional for the rotary movement. It can be a full closed-loop machine.

The table can work separately from the main machine with its own system and handwheel.

Parameters of Rotary Table

| Item | HT10 | HT20 | HT30 | HT40 | HT50 | HT100 | HT200 |

| Table Size (mm) | 1500x1500 | 1500x2000 | 2000x2000 | 2500x2500 | 2500x3000 | 2500x3000 | 3000x3500 |

| Max Load of Table (T) | 10 | 20 | 30 | 40 | 50 | 100 | 200 |

| Linear Travel of Table (mm) | 1500 | 1500 | 2000 | 2000 | 2500 | 3000 | 3000 |

| System | Fanuc /Siemens | Fanuc/ Siemens | Fanuc/ Siemens | Fanuc/ Siemens | Fanuc/ Siemens | Fanuc/ Siemens | Fanuc/ Siemens |