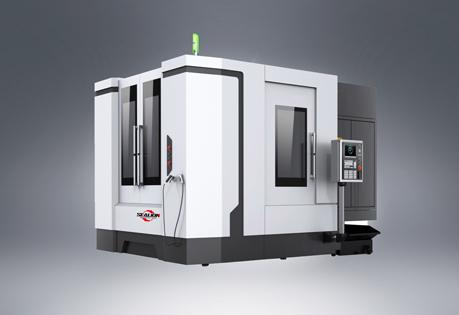

Vertical Machining Center

Vertical Machining Center shows its superiority in mold processing. It is the preferred CNC machine tool for small and medium-sized mold parts processing industry. You can do milling, boring, drilling, expanding, reaming, tapping, and other processes in one set-up. A wide range of VMC is for your selection.

Features of Vertical Machining Center

VMC Series Vertical CNC Machining Center is a new generation of CNC machine tools supplied by our company.

The X, Y, and Z axes can be equipped with a unique linear rolling guide or hardened plastic-bonded guideway.

VMC Series machines use an automatic tool exchange system (ATC), automatic lubrication system, cooling system, automatic chip removal device, manual spray gun, and portable operation device (MPG). All machines are fully protected with a modern cover.

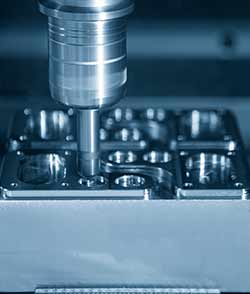

It is not only suitable for the processing of plates, shells, and precision parts,but also suitable for the processing of different kinds of molds.

Once the job is loaded on the table, it can do different processing, such as milling, boring, drilling, expanding, reaming, tapping, etc.

The advantages of the machines are high automation, high reliability, easy to operate. The modern design is highly favored by customers all over the world.

The CNC rotary table can also be installed on the machine tool, the table can be indexed by the system.

Working Principle of Vertical Machining Center

The working principle of the vertical machining center is to automatically process the parts processing program by manual processing procedures according to the part drawings, and convert the various machine tools and all the process parameters required by the parts into acceptable information codes. To the CNC device of the machine tool. These codes are stored on an information carrier (punched tape, disk, etc.), which is sent to the input device. Read the information and send it to the numerical control device, or use the computer to directly communicate with the machining center to realize the input and output of the part program.

Advantages of Vertical Machining Center

All castings are built with high tensile Meehanlte FC-30 high alloy cast irons, which provide outstanding wear-resistance.

The slideway of the cnc machine tool is equipped with a turn cite-b wear-resistant plate, precision spading, and forced lubrication to improve precision life. Three-axis square slide structure, and after heat treatment hardening, precision grinding.

The z-axis is equipped with counterweight balance, and the head rapid feed action and micro feed are very smooth.

A fully protected guideway makes sure the chips and coolant do not go into the guideway, extending the machine life.

MIS Data Collecting system.

Parameters of Vertical Machining Center

| Item | Unit | VDM650 | VDM850 | VDM1060 | VDM1270 | VDM1580 |

| Table Size | mm | 800x500 | 850x500 | 1050x560 | 1300x600 | 1550x740 |

| T-Slot | mm | 3x18x160 | 3x18x160 | 5x18x110 | 5x18x125 | 5x22x140 |

| Max Load | Kg | 500 | 500 | 800 | 1200 | 1500 |

| Spindle Center to Column | mm | 560 | 560 | 615 | 715 | 810 |

| Spindle Nose to Table | mm | 130~640 | 130~640 | 150~660 | 130~790 | 150~810 |

| X/Y/Z Travel | mm | 620/500/510 | 820/500/510 | 1020/550/510 | 1220/650/660 | 1530/740/660 |

| X/Y/Z Rapid Speed | m/min | 36/36/30 | 36/36/30 | 36/36/30 | 36/36/30 | 24/24/20 |

| X/Y/Z Feeding Speed | m/min | 1~20 | 1~20 | 1~20 | 1~10 | 1~10 |

| Spindle Motor Power | KW | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 |

| Max Spindle Speed | r/min | 10000 OP15000 | 10000 OP15000 | 10000 OP15000 | 6000 OP8000 | 6000 OP8000 |

| Spindle Taper | BT40 | BT40 | BT40 | BT50 | BT50 | |

| Max Tool Weight | Kg | 8 | 8 | 8 | 20 | 20 |

| Max Tool Dia(Full/Empty) | mm | 78/150 | 78/150 | 78/150 | 110/200 | 110/200 |

| Tool Change Time | Sec | <2 | <2 | <2 | 2 | 2 |

| X/Y/X Positioning Accuracy | mm | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| X/Y/Z Repeatability | mm | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 |

| System | Fanuc 0i-MF | Fanuc 0i-MF | Fanuc 0i-MF | Fanuc 0i-MF | Fanuc 0i-MF | |

| Overall Diamension | mm | 3280x2310x2700 | 3280x2310x2700 | 3430x2880x2800 | 3738x3264x2956 | 4163x4001x3296 |

| Weight | Kg | 6000 | 6500 | 7000 | 8500 | 10500 |

Configuration List of Vertical Machining Center

| Standard Feature | Optional Feature | Controller Option |

| Arm type 24T ATC | #40 Belt-driven spindle 10000rpm | Mitsubishi M80 |

| Coolant system | Arm type 32T ATC system | Fanuc 0i-MF |

| The floating tool clamp system | Arm type 40T ATC system | Fanuc 31i |

| Auto. lubrication system | Chain type chip conveyor & cart | Siemens 828D |

| Work lamp | Water curtain | Siemens 840D SL |

| Spindle air blast | Auto. tool length measuring device | Heidenhain |

| Work air blast | Auto. workpiece measuring device | Fagor |

| Auto. power off (M30) | Coolant through spindle | |

| RS-232 interface | Coolant through the tool holder | |

| Heat exchanger for the elect. cabinet | 4th Axis rotary table | |

| Leveling bolts & pads | Transformer | |

| Adjust tools & toolbox | CE Regulation | |

| Fully enclosed splash guard | ||

| Rigid tapping | ||

| Spindle oil cooler | ||

| Dual spiral type chip conveyor in Y-axis | ||

| Y-axis adopts 4-box-way design | ||

| Powerful chip flush system |