Horizontal Lathe

As a professional horizontal lathe supplier, Sealion Machine Tool supplies a wide range of horizontal lathe machine for sale. CNC type or conventional type, flat bed or slant bed, horizontal turning lathe, horizontal milling machine, horizontal turret lathe. It is your choice. We keep a high-level quality standard of our lathe machines. Those kinds of horizontal lathe machines are suitable for general machining work, such as turning, milling, threading, drilling, etc. All kinds of accessories are also available for different machines. This kind of horizontal CNC lathe is suitable for multiply kinds and small-medium batch productions, horizontal turning center, especially super for complicated and high accuracy parts. If you are interested in our horizontal lathe machines, please feel free to contact us!

-

This series of CNC lathe is using Fanuc or Siemens CNC control on the X&Z axis. It is suitable for energy, chemical, light industry, electromechanical, paper-making, automobile, aerospace, and aviation industries.

This series of CNC lathe is using Fanuc or Siemens CNC control on the X&Z axis. It is suitable for energy, chemical, light industry, electromechanical, paper-making, automobile, aerospace, and aviation industries. -

Slant bed CNC lathes are the China leading and advanced world-level machines developed by our company. They are widely used to handle the disk-like and shaft-like parts for the defence, automotive, mould and die, bearing production, oil and mining machinery manufacturing sectors.

Slant bed CNC lathes are the China leading and advanced world-level machines developed by our company. They are widely used to handle the disk-like and shaft-like parts for the defence, automotive, mould and die, bearing production, oil and mining machinery manufacturing sectors. -

-

Horizontal lathes are capable of various turning applications, mainly used for Inner Diameter and Outer Diameter, cylindrical face, taper surface, and other parts that feature rotating surface. The lathe is suited for face turning, grooving, parting, drilling, and another popular metric, inch, module, and diametral pitch threads.

Horizontal lathes are capable of various turning applications, mainly used for Inner Diameter and Outer Diameter, cylindrical face, taper surface, and other parts that feature rotating surface. The lathe is suited for face turning, grooving, parting, drilling, and another popular metric, inch, module, and diametral pitch threads.

Characteristics of Horizontal Lathe

1. The bed and oil pan of the horizontal lathe adopts the integral casting structure, which has high rigidity and good shock resistance, and is in line with the characteristics of high-speed cutting machine tools.

2. The bed head box adopts three support structures, and the three supports are tapered roller bearings. The spindle is easy to adjust, the rotation precision is high, and the precision retention is good.

3. The horizontal lathe is equipped with a four-station automatic feed mechanical stop device. The longitudinal position of the workpiece can be set by adjusting the longitudinal position of the cam on the stop bar to realize the longitudinal dimensioning of the part.

4. The design of the lathe lubrication system is reasonable and reliable. The front box, the feed box and the slide box are all splashed and lubricated in the body, and the line pump and plunger pumps are added to automatically forcibly lubricate the special parts.

Features of Horizontal Lathe

1. The bed, foot, oil pan, etc. of the lathe adopt an integral casting structure with high rigidity and good shock resistance, which is in line with the characteristics of high-speed cutting machine tools.

2. The head stock adopts the structure of three bearings, all of which are tapered roller bearings. The spindle is easy to adjust, with high rotation accuracy and good accuracy retention.

3. The feed box is equipped with a metric-inch thread conversion mechanism, which is convenient and reliable for the selection and conversion of thread types.

4. There is a cone clutch safety device in the slide box to prevent damage to the parts after the automatic knife is overloaded.

5. The horizontal lathe machine tool is equipped with a four-station automatic feed mechanical stop device in the longitudinal direction. By adjusting the longitudinal position of the cam on the stop lever, the required length of the work piece can be set to realize the longitudinal dimension processing of the parts.

6. The tail stock is equipped with a variable speed device, which can meet the needs of drilling and reaming.

7. The design of the cnc horizontal lathe machine lubrication system is reasonable and reliable. The head box, feed box, and slide box are all internally splash lubricated, and line pumps and plunger pumps are added for automatic forced lubrication of special parts.

-

SEALION has good experience in the development of specific but cheap machine tools that ensures precision and quality required in the energy sector.

SEALION has good experience in the development of specific but cheap machine tools that ensures precision and quality required in the energy sector.

-

At present, the construction machinery industry has a considerable scale, which can produce more than 3000 varieties of quality machine tools in 18 categories.

At present, the construction machinery industry has a considerable scale, which can produce more than 3000 varieties of quality machine tools in 18 categories.

-

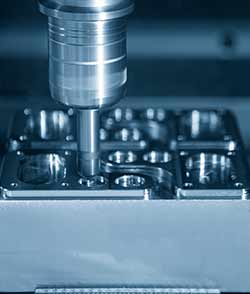

Quality machine tools can do machining from raw blocks, machining in roughing and fine finishing, machining all kinds of molds and mold-holders in both vertical or horizontal positions.

Quality machine tools can do machining from raw blocks, machining in roughing and fine finishing, machining all kinds of molds and mold-holders in both vertical or horizontal positions.

-

We offer a wide range of quality machine tools for your general machining and fabrication work in your factory.

We offer a wide range of quality machine tools for your general machining and fabrication work in your factory.

-

SEALION has a wealth of experience in the field of the motor for more than twenty years.

SEALION has a wealth of experience in the field of the motor for more than twenty years.