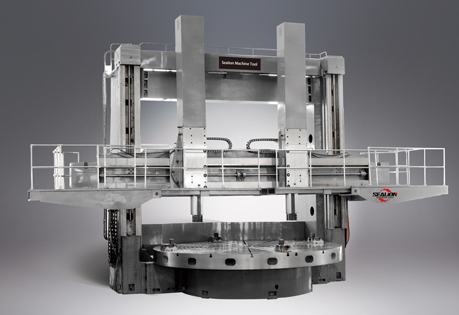

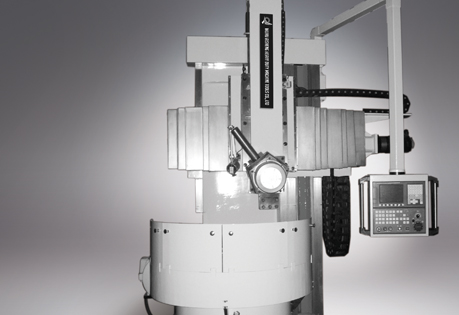

2-Axis CNC Single Column Vertical Lathe

2-Axis CNC Single Column Vertical Lathe X&Z is using a brand linear guideway. The main transmission of 2 axis cnc lathe is driven by frequency or a servo motor, simple structure, and high transmission efficiency. CNC Servo motor and gearbox directly drive the Ballscrew for X&Z axis feeding. This Single Column Vertical Lathe can reach high accuracy and fast-moving. The machine can equip an optical ruler to realize full close loop control.

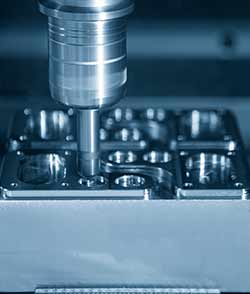

Application Fields of 2-Axis CNC Single Column Vertical Lathe