Lathe

Lathe machine introduction: Sealion Machine Tool supplies both vertical and horizontal lathe. We keep a high-level quality standard of our lathe machines for sale.

Types of cnc lathes include high precision Chinese CNC lathe machine type or conventional type, and we have a precision lathe for sale. It is your choice. Those kinds of the high precision CNC lathe are suitable for general machining work, such as turning, milling, threading, drilling, etc. All kinds of accessories are also available for different machines.

Lathe machine is widely used in chemical, mining, shipping, general metal goods, and other mold machining industries. Sealion's Chinese CNC Lathe Machine for sale is famous for its reliable quality, super service, and fast delivery. It has been supplied both domestic and overseas.

-

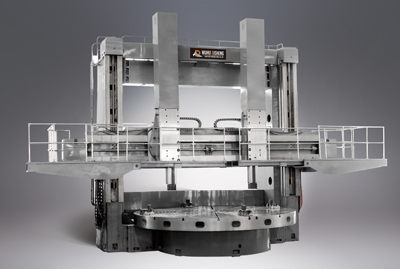

Sealion Machine Tool supplies a wide range of vertical lathe. CNC type or conventional type, single column or double column, it is your choice. We keep a high-level quality standard of our lathe machines.

Sealion Machine Tool supplies a wide range of vertical lathe. CNC type or conventional type, single column or double column, it is your choice. We keep a high-level quality standard of our lathe machines. -

Sealion Machine Tool supplies wide range of horizontal lathe. CNC type or conventional type, flat bed or slant bed, it is your choice. We keep a high level quality standard of our lathe machines.

Sealion Machine Tool supplies wide range of horizontal lathe. CNC type or conventional type, flat bed or slant bed, it is your choice. We keep a high level quality standard of our lathe machines.

Vertical Lathe Vs Horizontal Lathe

There are horizontal lathes and vertical lathes. The main axis of a vertical lathe is parallel to gravity, while the main axis of a horizontal lathe is parallel to the floor. However, these structural differences have a great impact on the function of the machine. Although horizontal lathes may be well-known and popular, the advantages and possibilities of vertical lathes cannot be underestimated.

The use of gravity side by side not only makes clamping easier, but also applies greater cutting force. This can increase chip removal rate and reduce cycle time. Therefore, vertical turning is much more productive than horizontal turning. Another advantage of vertical lathes that is often underestimated is that vertical lathes generally require less floor space than horizontal lathes.

Although vertical lathes have many advantages, some functions can only be achieved by horizontal lathes. Especially when turning long workpieces, the horizontal lathe has shown its own strength. The ability to use fixtures, tailstocks, and possibly even fixed or following brackets to mount parts allows turning workpieces, such as long shafts.

- Slant Bed CNC Lathe

- Opposit Face Floor Boring And Milling Machine

- Vertical Machining Center

- Horizontal Machining Center

- Table Type Horizontal Boring Machine

- FT200/FT300 CNC SLANT BED LATHE

- 2-Axis CNC Double Column Vertical Lathe

- Single Column Vertical Lathe

- Double Column Vertical Lathe

- Gantry Machining Center

- CNC Horizontal Boring Mill

- Floor Type Boring Mill

-

SEALION has good experience in the development of specific but cheap machine tools that ensures precision and quality required in the energy sector.

SEALION has good experience in the development of specific but cheap machine tools that ensures precision and quality required in the energy sector.

-

At present, the construction machinery industry has a considerable scale, which can produce more than 3000 varieties of quality machine tools in 18 categories.

At present, the construction machinery industry has a considerable scale, which can produce more than 3000 varieties of quality machine tools in 18 categories.

-

Quality machine tools can do machining from raw blocks, machining in roughing and fine finishing, machining all kinds of molds and mold-holders in both vertical or horizontal positions.

Quality machine tools can do machining from raw blocks, machining in roughing and fine finishing, machining all kinds of molds and mold-holders in both vertical or horizontal positions.

-

We offer a wide range of quality machine tools for your general machining and fabrication work in your factory.

We offer a wide range of quality machine tools for your general machining and fabrication work in your factory.

-

SEALION has a wealth of experience in the field of the motor for more than twenty years.

SEALION has a wealth of experience in the field of the motor for more than twenty years.