Demystifying Milling Machine Structure: A Closer Look at its Components

Milling machines are the workhorses of precision machining, enabling the creation of intricate parts and components across various industries. Behind their capability lies a complex and well-engineered structure that facilitates precise material removal. In this article, we delve into the milling machine structure, exploring their essential components and the role they play in achieving accuracy and versatility.

The Foundation: Base and Column

At the core of every milling machine is its base and column. The base provides stability and support, ensuring that the machine remains rigid during operation. The column, often vertically oriented, serves as the backbone that supports the moving components and the spindle. The rigidity of the base and column is crucial for maintaining precise cutting movements.

Guiding the Way: Knee, Saddle, and Table

Milling machines feature a movable table that holds the workpiece and moves in the X and Y directions. The saddle is mounted on the knee, allowing the table to move along the Z-axis. The knee can be adjusted vertically, enabling the table to be positioned at different heights. These components work in tandem to guide the workpiece and the cutting tool, allowing for precise material removal and various machining operations.

The Heart of Machining: Spindle and Toolholder

The spindle is the heart of the milling machine, responsible for rotating the cutting tool at high speeds. It's typically driven by a motor and is equipped with a toolholder that securely holds the cutting tool. The toolholder ensures accurate tool positioning and minimizes vibrations, which are crucial for achieving precise cuts and surface finishes.

Power and Precision: Drive Mechanisms

Milling machines employ various drive mechanisms to move the table, saddle, and knee. These mechanisms can include lead screws, ball screws, and linear guides. The choice of drive mechanism impacts the machine's accuracy, speed, and overall performance. Modern machines often incorporate CNC (Computer Numerical Control) systems that precisely control these mechanisms, enabling automated and highly accurate machining.

Versatility in Action: Rotating Head and Tool Changer

Some milling machines offer enhanced versatility through a rotating head or spindle. This feature allows the cutting tool to be positioned at different angles, enabling complex machining operations and the creation of intricate geometries. Additionally, advanced machines may feature automatic tool changers, allowing for seamless tool swaps during a machining process, further enhancing efficiency and reducing downtime.

The milling machine structure is a harmonious assembly of components, each playing a vital role in achieving precision, versatility, and efficiency in machining operations. From the base and column providing stability to the spindle and toolholder ensuring accurate material removal, every element contributes to the overall performance of the machine. Understanding the intricate interplay of these components helps manufacturers harness the full potential of milling machines, turning raw materials into finely crafted components that power various industries.

-

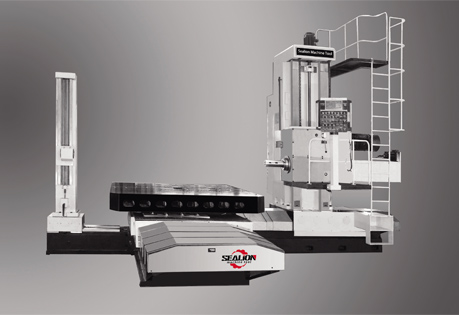

Components and Construction of Horizontal CNC Boring Bars

In today's advanced manufacturing industry, the use of Horizontal CNC Boring Bars has become crucial for precision drilling and boring applications. These sophisticated machines offer a range of c... -

The Future of Furniture: Automated Milling Machines in Customized Woodwork

As we step into a new era of craftsmanship, the furniture industry is witnessing a transformative wave, thanks to the integration of cutting-edge technology. At the forefront of this revolution are au... -

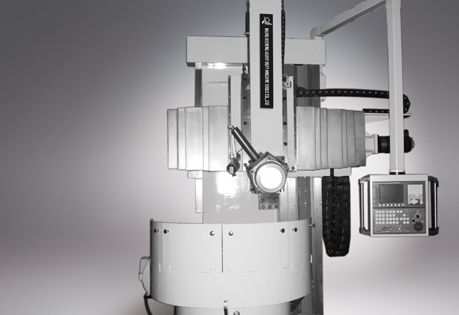

Single Column Vertical Lathe Transmission System

The main movement of the single-column vertical lathe is the rotary movement of the table, and the feed movement is the movement of the vertical frame in the horizontal and vertical directions.The aux...