Operations and Capabilities of Sealion's Horizontal Lathe Machines

In modern manufacturing industries, horizontal lathe machines have become an integral part of the machining process. With their exceptional precision, versatility, and efficiency, these machines play a crucial role in shaping various components and delivering superior results. In this blog, we will explore the operations and capabilities of Sealion's horizontal lathe machines, a reliable brand known for its innovative solutions.

The Basics of Horizontal Lathe Machines

Horizontal lathe machines are a fundamental tool in the metalworking industry. These machines consist of a horizontal bed, a headstock, a tailstock, and a saddle. The workpiece, positioned on the bed, rotates as a cutting tool moves along it to remove material, generating a desired shape. Sealion's horizontal lathe machines excel in this process, delivering exceptional precision and accuracy for complex machining operations.

Operations and Applications

Sealion's horizontal lathe machines are a versatile solution for a wide range of machining tasks. Let's delve into the primary operations and applications where these machines excel:

Turning: Turning is the most common operation performed on horizontal lathe machines. It involves the process of removing excess material from the workpiece to create cylindrical shapes, such as shafts and rods. Sealion's machines offer exceptional control and precision during turning operations, ensuring consistent and accurate results.

Threading: Horizontal lathe machines are also suitable for threading operations. With the help of specialized tooling, these machines can create external or internal threads on the workpiece. This capability allows for the production of threaded components, such as bolts, nuts, and screws, with consistent thread quality and accuracy.

Facing: In facing operations, the horizontal lathe machine enables the removal of material from the end face of a workpiece, creating a smooth and flat surface. Sealion's machines offer excellent control in facing applications, allowing for precise machining of large workpieces.

Taper turning: With a horizontal lathe machine, taper turning is made easy. By adjusting the position and angle of the cutting tool, these machines can create tapering profiles on the workpiece accurately. This capability is particularly useful in applications such as producing tapered shafts or creating mating components with tapering features.

Boring: Sealion's horizontal lathe machines also excel in boring operations. Boring involves enlarging an existing hole or creating a new hole with precise internal dimensions. This capability is crucial for manufacturing various components, such as cylinders, engine blocks, and gearboxes, where precision and accuracy are paramount.

Sealion's Advantages and Technology

Sealion's horizontal lathe machines stand out due to their advanced features and cutting-edge technology. Here are a few advantages that make Sealion an ideal choice:

High precision and accuracy: Sealion employs state-of-the-art technology and rigorous quality control measures to ensure their machines deliver exceptional precision and accuracy in every operation.

Versatility: Sealion's horizontal lathe machines are equipped with multiple tool holders, allowing for the use of various cutting tools and enhancing the machine's versatility. This enables manufacturers to handle a diverse range of workpieces and machining requirements efficiently.

Advanced controls and automation: Sealion integrates advanced control systems into their machines, allowing for easy operation and efficient workflow. Automation features like programmable toolpaths ensure consistent and repeatable machining results.

Robust construction: Sealion's machines boast a sturdy design, ensuring long-term reliability and stability. These machines are built to withstand heavy-duty machining operations while minimizing vibration and enhancing overall machining quality.

Sealion's horizontal lathe machines offer exceptional operations and capabilities that cater to the diverse needs of modern manufacturing. With their precision, versatility, and advanced technology, these machines provide manufacturers with the necessary tools to achieve superior results. From turning to threading and facing to boring, Sealion's horizontal lathe machines exhibit excellence in every aspect, making them a trusted solution in the metalworking industry.

-

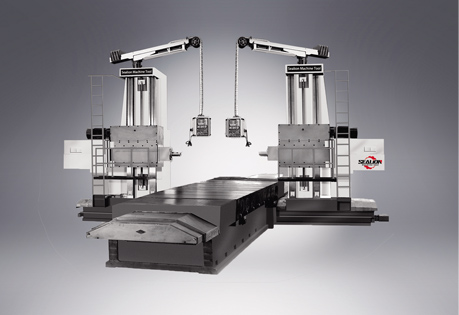

Enhancing Productivity and Efficiency with New Floor Type Boring Milling Machines

In today's competitive manufacturing industry, companies are continually striving to enhance productivity and efficiency to stay ahead of the curve. One of the key factors in achieving these goals... -

Quality and Stability in Floor Type Horizontal Boring Machines

When it comes to floor type horizontal boring machines, quality and stability are key factors that can greatly impact the efficiency and accuracy of drilling operations. These machines are essential f... -

From CNC Lathe to Lathe Accessories, How are They Produced?

CNC lathes are the main equipment engaged in machining today. During processing, the machine tool automatically positions and feeds according to the pre-input program, and completes the cutting of par...