Workpiece Holding and Positioning Mechanisms in Horizontal CNC Rotary Tables

As technology advances, the demand for efficient and precise manufacturing processes continues to rise. Horizontal CNC rotary tables have become a popular choice for industries that require high-precision machining and complex workpiece positioning. In this blog, we will explore the importance of workpiece holding and positioning mechanisms in horizontal CNC rotary tables, with a focus on the Sealion brand.

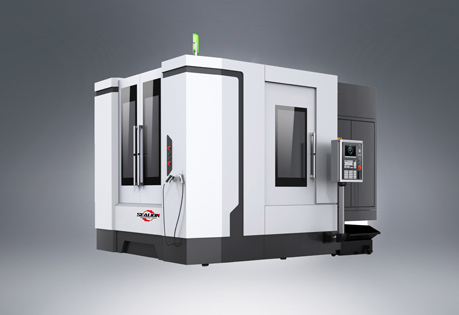

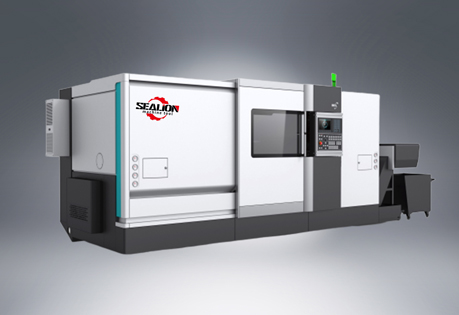

Overview of horizontal CNC rotary tables

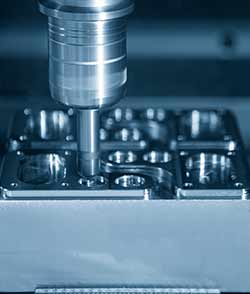

Horizontal CNC rotary tables are essentially a rotating platform that allows for the machining of workpieces from multiple angles. It plays a crucial role in enhancing productivity and accuracy in various industries such as aerospace, automotive, and medical devices. These tables can be operated manually or with the help of computer numerical control (CNC) systems.

Workpiece holding mechanisms

The first critical aspect of a horizontal CNC rotary table is its workpiece holding mechanism. The ability to securely hold the workpiece during machining operations is vital to avoid any potential accidents or inaccuracies. Sealion, a renowned brand in the industry, offers a wide range of workpiece holding mechanisms that are designed to provide maximum stability and precision.

Sealion's horizontal CNC rotary tables feature robust clamping systems that ensure a firm grip on the workpiece. These clamping systems are equipped with hydraulic or pneumatic devices to provide a strong and reliable hold. Additionally, Sealion's tables often come with customizable fixtures and jaws, allowing for easy adaptability to different workpiece shapes and sizes.

Positioning mechanisms

Accurate positioning of the workpiece is another crucial aspect of horizontal CNC rotary tables. Sealion recognizes this need and incorporates advanced positioning mechanisms in their tables to ensure precise machining. These mechanisms allow for precise angular positioning, ensuring that the workpiece is accurately aligned for the desired machining operation.

Sealion's positioning mechanisms utilize high-precision rotary encoders and servo motors to achieve precise positioning. These systems are integrated with the CNC control system, enabling operators to program the desired angles and positions for machining. As a result, the table can rotate and position the workpiece with an exceptional level of accuracy, reducing the chances of error and rework.

The combination of reliable workpiece holding and precise positioning mechanisms in Sealion's horizontal CNC rotary tables allows manufacturers to achieve higher productivity, improved quality, and reduced setup times. The versatility and flexibility provided by these mechanisms enable the machining of complex, multi-axis parts, further enhancing their appeal in various industries.

In conclusion, workpiece holding and positioning mechanisms play a vital role in horizontal CNC rotary tables. Sealion, with its commitment to quality and precision, offers a range of horizontal CNC rotary tables that incorporate robust workpiece holding mechanisms and advanced positioning systems. These mechanisms ensure secure workpiece clamping and precise angular positioning, contributing to the overall efficiency and accuracy of machining processes. When considering horizontal CNC rotary table options, Sealion's products are worth exploring for their reliability and performance.

-

Essential Maintenance and Troubleshooting Tips for Horizontal Lathe Machines

Horizontal lathe machines play a crucial role in various industries, enabling the precision shaping and machining of components. As with any machine, regular maintenance and the ability to troubleshoo... -

The 16th China International Machine Tool Exhibition (Cimt2019) Was Held In Beijing

On April 15, 2019, the 16th China International Machine Tool Exhibition (cimt2019), sponsored by China Machine Tool Industry Association and co sponsored by China International Exhibition Center Group... -

Unlocking the Versatility of Double Column Vertical Lathes in Various Industries

In the ever-evolving world of manufacturing and machining, the reliance on advanced machinery has become essential to meet the demands of precision and efficiency. A prime example of such a game-chang...