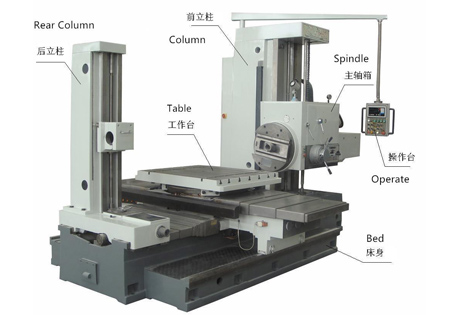

Features and Capabilities of Horizontal Turning Lathes

When it comes to machining metal workpieces, horizontal turning lathes are essential tools in any workshop. These machines are designed to efficiently and accurately shape cylindrical workpieces by rotating them while a cutting tool removes material from the surface. In this blog, we will explore the features and capabilities of horizontal turning lathes, discussing why they are a valuable asset for manufacturing operations.

Precision Machining

Horizontal turning lathes are known for their precision machining capabilities. These machines can produce highly accurate and consistent results, making them ideal for projects that require tight tolerances. The ability to control the rotational speed of the workpiece and the cutting tool allows for precise control over the shaping and finishing of the workpiece. This level of precision is essential for producing high-quality parts and components for various industries.

Versatile Machining Options

One of the key features of horizontal turning lathes is their versatility. These machines can handle a wide range of workpieces, from small, intricate parts to large, heavy-duty components. The ability to adjust the speed, feed rate, and cutting depth allows operators to tailor the machining process to the specific requirements of each workpiece. This versatility makes horizontal turning lathes a valuable asset for manufacturers who need to produce a variety of parts for different applications.

Efficient Operation

Horizontal turning lathes are designed for efficiency, allowing operators to quickly and easily produce high-quality parts in a cost-effective manner. These machines are equipped with advanced cutting tools and cutting strategies that minimize material waste and reduce production time. Additionally, the automated features of horizontal turning lathes, such as CNC controls and tool changers, streamline the machining process and eliminate the need for manual adjustments, resulting in faster and more consistent production.

Enhanced Productivity

Horizontal turning lathes are designed to improve productivity in machining operations. These machines can perform a wide range of machining operations, including turning, facing, threading, and grooving, in a single setup, eliminating the need for multiple machines and reducing production time. The continuous rotation of the workpiece allows for uninterrupted machining, resulting in higher throughput and faster completion of projects. With their high-speed capabilities and cutting-edge technology, horizontal turning lathes can significantly increase productivity and efficiency in manufacturing operations.

In conclusion, horizontal turning lathes are versatile, efficient, and productive machines that play a crucial role in modern manufacturing operations. With their precision machining capabilities, versatile machining options, efficient operation, and enhanced productivity, these machines are essential tools for producing high-quality parts and components for a wide range of industries. Whether you are a small machine shop or a large manufacturing facility, investing in a horizontal turning lathe can help you optimize your production process and stay ahead of the competition.

-

The Principle of CNC Turning Lathe Tool Setting

Ⅰ. The principle of CNC turning lathe tool settingI believe that everyone is already familiar with the "knife setting" in CNC turning lathe, but few people will "deeply study" the... -

Beyond Metal: Exploring the Versatility of CNC Milling Machines in Plastic Fabrication

In the world of manufacturing, the CNC milling machine has long been associated with metal fabrication. However, with advancements in technology and the development of new techniques, these powerful m... -

What Problems Should be Paid Attention to When Buying CNC Lathe Machine

Compared with general lathes, CNC lathes have many advantages, so many kinds of CNC lathe manufacturers are springing up. Among them, Shanghai Sealion Machine Tool Co., Ltd. is the most representative...