Green Precision: Sustainable Practices with Automated Milling in Eco-Friendly Production.

In the modern era, sustainability has become a pressing concern for industries all around the world. With the ever-increasing focus on environmental conservation, businesses are constantly seeking innovative solutions that can meet their production goals while minimizing their impact on the planet. One area where significant advancements have been made is in the field of automated milling machines. These machines have revolutionized the manufacturing process, providing both precision and sustainability in eco-friendly production.

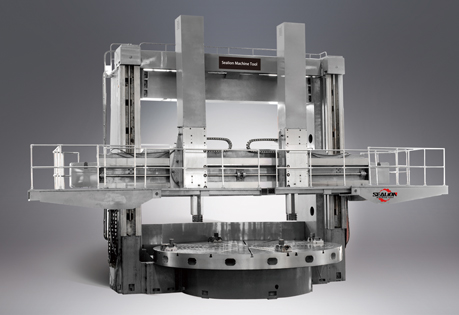

Sealion, a renowned brand in the manufacturing industry, is leading the way in sustainable practices with their automated milling machines. Designed with efficiency and eco-friendliness in mind, Sealion's automated milling machines offer numerous benefits to businesses looking to reduce their carbon footprint.

Efficient Resource Utilization

One of the primary advantages of automated milling machines is their ability to optimize resource utilization. These machines are equipped with advanced software that calculates the most efficient way to cut materials, thereby minimizing waste. By precisely cutting materials with minimal scrap, businesses can significantly reduce their overall consumption and contribution to landfill waste.

Energy Efficiency

Automated milling machines are designed to operate using energy-efficient technologies. Sealion's machines are equipped with advanced motors and drive systems that consume less energy compared to traditional milling machines. This energy-saving feature not only reduces the carbon footprint of the manufacturing process but also lowers operational costs for businesses in the long run.

Precision Engineering

Sealion's automated milling machines are engineered to deliver exceptional precision and accuracy. By utilizing state-of-the-art technology, these machines can produce intricate and complex designs with minimal errors. This level of precision reduces the need for rework, thereby saving additional resources and reducing waste. Automated milling machines ensure that every product is manufactured with the highest quality standards, meeting customer expectations while minimizing the use of resources.

Reduced Carbon Emissions

Traditional milling machines often require manual labor, resulting in higher levels of carbon emissions. However, with automated milling machines, the need for human intervention is minimized. This leads to a significant reduction in carbon emissions during the manufacturing process. By transitioning to automated milling machines, businesses can make substantial strides towards achieving their sustainability goals.

Sealion's commitment to sustainability goes beyond the design of their automated milling machines. The brand also ensures that their products are manufactured using eco-friendly materials and processes. By adopting rigorous environmental standards throughout their supply chain, Sealion sets an example for other manufacturers to follow.

In conclusion, automated milling machines have revolutionized the manufacturing process, providing businesses with both precision and sustainability. Sealion's automated milling machines are at the forefront of this innovation, offering efficient resource utilization, energy efficiency, precision engineering, and reduced carbon emissions. By incorporating these eco-friendly practices, businesses can not only meet their production goals but also contribute towards a greener, more sustainable future. With Sealion's automated milling machines, Green Precision in eco-friendly production is within reach.

-

How Does Machining Center Connect with Computer

CNC system of the machining center is often equipped with RS-232, CF card, DNC, Ethernet, and USB interface. How to connect the machining center with a computer depends on your CNC system and installa... -

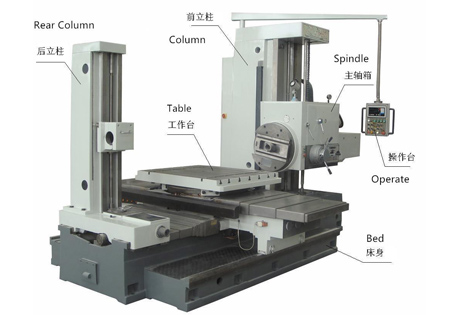

Underground Engineering: Exploring the Versatility of Horizontal Boring Mills in Tunneling Applications.

Tunneling has been a crucial method in various industries, from infrastructure development to mining operations. To achieve precision, efficiency, and safety in tunneling projects, advanced machinery ... -

Daily Maintenance and regular inspection of Machining Center

In the use of equipment, daily maintenance and regular inspections are essential. Good maintenance can keep the equipment in a good working condition, improve production efficiency and reduce costs.1....