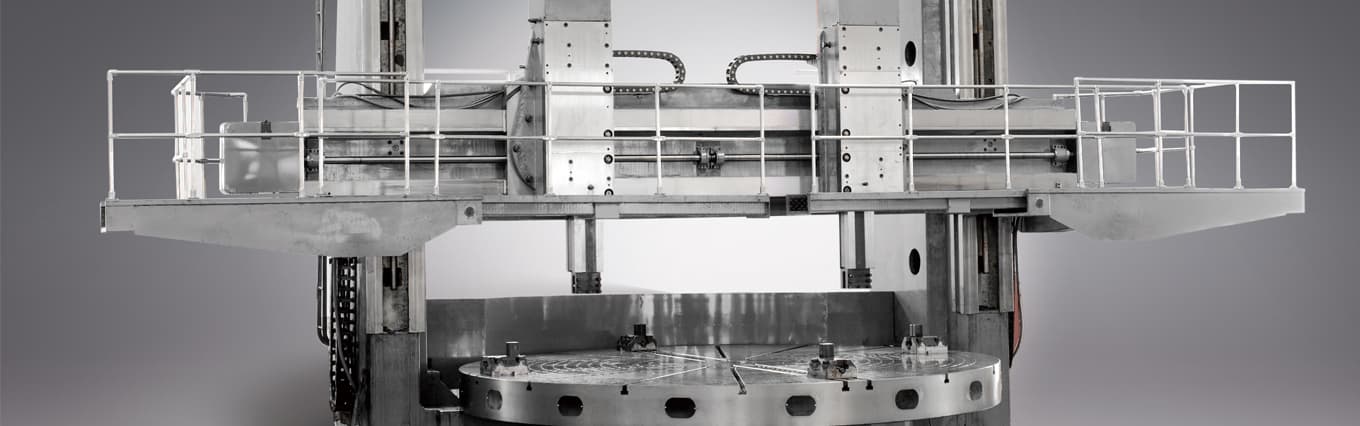

Advantages of Using Hydrostatic Rotary Tables for High Precision Machining

In the world of high precision machining, one piece of equipment that is essential for achieving accurate results is the hydrostatic rotary table. This innovative technology allows for unparalleled precision and control in the machining process, making it a valuable tool for industries that require intricate and precise machining capabilities.

Increased precision

One of the main advantages of using a hydrostatic rotary table is the increased precision that it offers. The hydrostatic bearings used in these tables provide a smooth and stable rotation, allowing for incredibly accurate positioning of the workpiece. This level of precision is essential for industries such as aerospace and medical, where even the slightest deviation can result in costly errors.

Better surface finish

Another key advantage of using hydrostatic rotary tables is the improved surface finish that they provide. The smooth and consistent rotation of the table minimizes vibrations and ensures that the machining process is carried out with maximum precision. This results in a higher quality surface finish on the workpiece, reducing the need for additional finishing processes and saving time and money in the long run.

Increased productivity

In addition to improved precision and surface finish, hydrostatic rotary tables also offer increased productivity. The stable and reliable rotation of the table allows for faster machining speeds and higher feed rates, leading to shorter cycle times and increased throughput. This means that manufacturers can produce more parts in less time, ultimately improving efficiency and profitability.

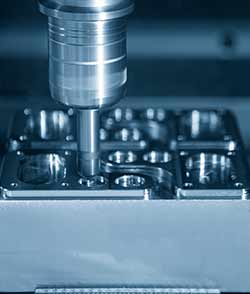

Longer tool life

Finally, using a hydrostatic rotary table can also lead to longer tool life. The smooth and consistent rotation of the table reduces wear and tear on cutting tools, extending their lifespan and reducing the need for frequent tool changes. This not only saves money on tooling costs but also ensures that the machining process remains consistently accurate and reliable.

Overall, the advantages of using hydrostatic rotary tables for high precision machining are clear. From increased precision and better surface finish to improved productivity and longer tool life, these tables offer a range of benefits that make them an essential tool for industries that require precise and intricate machining capabilities. By investing in a hydrostatic rotary table, manufacturers can achieve superior results and gain a competitive edge in today's demanding market.

-

The Importance of Safety and Ergonomics When Using CNC Turntables

In the fast-paced manufacturing industry, CNC turntables have become essential tools for enhancing productivity and precision. These ingenious machines allow for swift and seamless rotation of workpie... -

The 16th China International Machine Tool Exhibition (Cimt2019) Was Held In Beijing

On April 15, 2019, the 16th China International Machine Tool Exhibition (cimt2019), sponsored by China Machine Tool Industry Association and co sponsored by China International Exhibition Center Group... -

Analysis of Reasons for Tool Position Deviation in CNC Lathes

Because the tool measuring system is based on the lathe system itself, and the processing of CNC lathe is completed through programmed control, the determination and use of coordinate systems are very...