Rotary Resilience: The Importance of Rotary Tables in Heavy Machinery Manufacturing

In heavy machinery manufacturing, precision, efficiency, and versatility are the bedrock of success. One often-overlooked tool that plays a critical role in achieving these goals is the rotary table. In this blog post, we will explore the significance of rotary tables in heavy machinery manufacturing and show how Sealion's innovative rotary tables are revolutionizing the industry.

Understanding Rotary Tables in Heavy Machinery Manufacturing

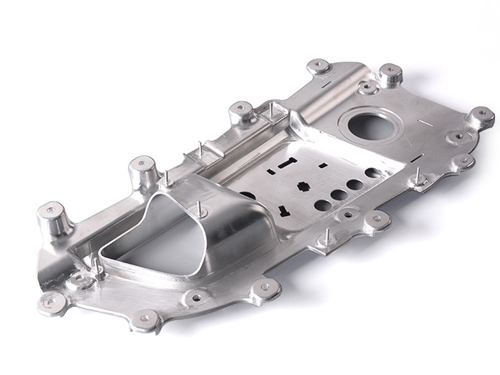

Rotary tables are horizontal tables that mount onto the working surface of heavy machinery, allowing for the precise rotation and positioning of components during the manufacturing process. These tables can be operated manually or automated, ensuring that materials are precisely aligned for drilling, milling, or grinding operations.

With their ability to rotate components at various angles, rotary tables excel at producing complex shapes and intricate details with superior accuracy. Additionally, their versatility allows manufacturers to save time and resources as they can perform multiple operations without having to reset the workpiece.

By incorporating a rotary table into heavy machinery manufacturing processes, manufacturers can achieve enhanced productivity, reduced setup time, and improved product quality – all translating to significant cost savings and a competitive edge in the market.

Sealion Rotary Tables: The Epitome of Excellence

Sealion has established itself as a trusted leader in the manufacturing of rotary tables. With a relentless commitment to research and innovation, Sealion's rotary tables are engineered to meet the demanding needs of heavy machinery manufacturers.

Equipped with precise bearings and a robust drive system, Sealion rotary tables provide unparalleled accuracy and reliability, even under the most challenging operating conditions. Their seamless integration with popular heavy machinery systems ensures effortless compatibility and ease of use.

Moreover, Sealion offers a diverse range of rotary tables, from compact models for small-scale machinery to larger units capable of handling heavy loads. This versatility ensures that manufacturers can find the perfect rotary table to suit their specific manufacturing requirements.

Advantages and Applications of Rotary Tables

The advantages of employing Sealion rotary tables in heavy machinery manufacturing extend beyond improved precision and efficiency. These powerful tools also enable manufacturers to achieve superior surface finishes, reduced scrap rates, and enhanced productivity. As a result, businesses can deliver high-quality products that meet or exceed customer expectations.

Rotary tables find extensive applications in industries ranging from automotive and aerospace to mold making and electronics. Whether it's the production of engine components, turbine blades, or intricate electronic circuit boards, rotary tables play a vital role in ensuring consistent and accurate manufacturing outcomes.

The Future of Rotary Tables: Innovating Manufacturing Processes

As heavy machinery manufacturing continues to evolve, the importance of rotary tables grows even more crucial. Technological advancements will drive the development of even more advanced rotary table systems, incorporating features like real-time feedback and intelligent automation. Sealion remains at the forefront of this innovation, consistently pushing the boundaries of rotary table capabilities and revolutionizing manufacturing processes.

In conclusion, rotary tables serve as the backbone of heavy machinery manufacturing, enabling precision, efficiency, and versatility. Sealion's commitment to excellence guarantees that their rotary tables deliver the utmost performance, paving the way for increased productivity and success in the industry.

-

Classification of CNC Machine tools According to Control Mode

1. Open-loop control CNC centre latheThis kind of machine tool does not have the position detection feedback device and usually uses the stepping motor as the actuator. The input data is processed by ... -

Workpiece Holding and Positioning Mechanisms in Horizontal CNC Rotary Tables

As technology advances, the demand for efficient and precise manufacturing processes continues to rise. Horizontal CNC rotary tables have become a popular choice for industries that require high-preci... -

Characteristics and Advantages of Different Types of CNC Machine Structures

CNC machines have revolutionized the manufacturing industry by streamlining processes and enhancing precision. One crucial aspect that influences their performance is their structure. In this blog, we...