Types of CNC Machine Structures

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by providing automation and precision in machining processes. These machines are widely used in various industries, including automotive, aerospace, and electronics, to efficiently produce complex parts and components. One crucial aspect that sets CNC machines apart is their diverse structures, which determine their capabilities and applications. In this blog, we will explore three common types of CNC machine structures and their benefits.

Box Frame Structure

The box frame structure is one of the most common types of CNC machine structures. As the name suggests, it is composed of a solid box-like frame that provides stability and rigidity to the machine. This design ensures accurate and consistent machining results, even when dealing with heavy workpieces. The robust construction of the box frame structure minimizes vibrations and enhances cutting performance, allowing for high-speed machining without compromising precision. Additionally, this structure enables better access to the working area, facilitating easier tool changes and maintenance procedures.

Column and Knee Structure

The column and knee structure is another widely used design in CNC machines. This structure consists of a vertical column that supports a horizontal knee. The knee can be adjusted to move along the column, providing versatility in positioning the workpiece and tooling. The column and knee structure offers excellent flexibility and adaptability, making it suitable for machining a wide range of parts. This structure is commonly found in milling machines, where the adjustable knee allows for multi-axis machining operations.

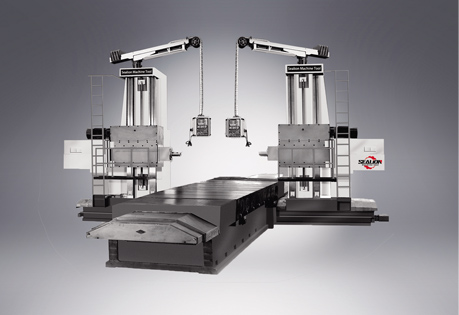

Gantry Structure

The gantry structure is often seen in CNC machines used for large-scale machining applications. Unlike the box frame and column and knee structures, the gantry structure features an overhead design that resembles a bridge. This design enables a long and wide span, offering exceptional stability and precision during machining. Gantry machines are typically used for tasks requiring a high level of accuracy, such as cutting large sheets of material or creating molds for intricate shapes. The gantry structure also allows for simultaneous multi-axis machining, increasing efficiency and reducing production time.

In conclusion, the structure of a CNC machine plays a vital role in its performance and capabilities. The box frame structure ensures stability and accuracy, while the column and knee structure offers flexibility for various machining operations. On the other hand, the gantry structure is ideal for large-scale precision machining tasks. However, it is worth noting that there are other types of CNC machine structures available as well, each with its unique advantages and applications.

Investing in a CNC machine with the right structure for your specific needs can significantly improve production efficiency and quality. Therefore, it is crucial to thoroughly understand the various machine structures before making a purchase decision. Whether you require high-speed machining, multi-axis capabilities, or large-scale precision, there is a CNC machine structure suitable for your requirements.

Sealion is a leading brand known for manufacturing CNC machines that incorporate diverse structures to meet different industry demands. Their range of CNC machines is designed with reliability, performance, and precision in mind. By investing in a Sealion CNC machine, you can be confident in achieving optimal results for your machining operations.

In conclusion, the CNC machine structure is a critical factor that determines the overall performance and capabilities of these advanced manufacturing tools. Understanding the different types of structures available, such as the box frame, column and knee, and gantry structures, allows manufacturers to choose the most suitable option for their specific needs. By investing in a high-quality CNC machine, such as those offered by Sealion, businesses can enhance their productivity, efficiency, and competitiveness in the market.

-

The Impact of Double Column Vertical Lathes on Modern Industry

In today's rapidly evolving industrial landscape, the role of Double Column Vertical Lathes cannot be overstated. This advanced machinery has revolutionized the way modern industries operate, offe... -

Characteristics, Processing Route and Advantages of CNC Lathes

Ⅰ. What is CNC lathe?CNC lathes are currently one of the wide range of control machines. It is mainly used for shaft-type parts or inner and outer cylindrical surfaces of the disk-type part, an inter... -

Enhancing Productivity and Efficiency with New Floor Type Boring Milling Machines

In today's competitive manufacturing industry, companies are continually striving to enhance productivity and efficiency to stay ahead of the curve. One of the key factors in achieving these goals...