CNC Lathe & Robot Can Realize Lathe Automation

1. Combination of "vertical CNC machining center & horizontal CNC machining center & industrial robot"

A vertical CNC machining center and a horizontal CNC machining center cooperate with the robot to complete the production and processing. The rotating double exchange table can greatly save the time of disassembly and assembly of the workpiece, improve the work efficiency and save the cost. Among them, the horizontal machining center can be equipped with a single table or a double exchange table.

2. Combination of "vertical CNC machining center & industrial robot"

Two vertical CNC machining centers cooperate with industrial robots, which are also called CNC lathe robots to complete production and processing. The rotating double exchange table can greatly save the time of disassembly and assembly of the workpiece, improve the work efficiency and save the cost.

3. Combination of "CNC lathe & industrial robot"

Two CNC lathes cooperate with industrial robots to complete production and processing. After a workpiece is processed on one side of a CNC lathe, it can be transferred to a second lathe by an industrial robot to process the reverse side.

4. Combination of "horizontal CNC machining center & CNC lathe plus six-axis robot"

A CNC lathe, a horizontal CNC machining center and a six-axis robot cooperate to complete the production and processing. The rotating double exchange table can greatly save the time of disassembly and assembly of workpieces, improve work efficiency and save costs. Among them, the horizontal machining center can be equipped with a single table or a double exchange table.

5. Combination of "vertical CNC machining center & CNC lathe plus robot"

A vertical CNC machining center, a CNC lathe and industrial robots cooperate to complete the production and processing. The rotating double exchange table can greatly save the time of disassembly and assembly of the workpiece, improve the work efficiency and save the cost.

-

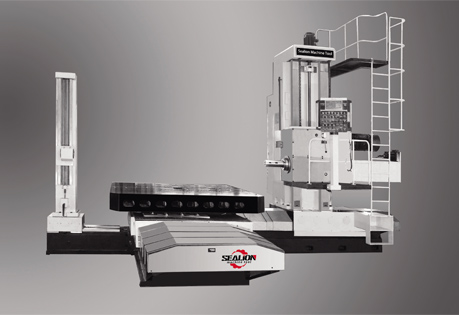

Maintenance and Operation Procedures for Horizontal Boring Machine

The operator of horizontal boring machine must be familiar with the general performance and structure of the machine, transmission system, and over-performance use is strictly prohibited.Before operat... -

Troubleshooting issues of CNC lathe

CNC lathe is one of the most widely used CNC machines. It is mainly used for cutting machining of axial parts or disc parts such as inner and outer cylindrical surfaces, inner and outer conical surfac... -

Analysis on Common Fault of CNC Turing Lathe System

Ⅰ. Common faults of CNC turning lathe systemCNC turning lathe system faults can also be divided into mechanical faults and electrical faults. Because the same fault phenomenon may be caused by both e...