Design and Construction of Hydrostatic Rotary Tables

When it comes to precision machining, every detail matters. From the quality of the materials used to the design and construction of the machinery, every aspect plays a crucial role in ensuring the desired outcomes. One essential component that is often overlooked but plays a significant role in precision machining is the hydrostatic rotary table.

What is a hydrostatic rotary table?

A hydrostatic rotary table is a type of rotary table that uses a thin layer of oil or fluid to create a film of lubrication between the moving parts. This results in a smoother rotation and allows for higher levels of precision and accuracy in machining processes. The use of hydrostatic technology also helps to reduce wear and tear on the machinery, prolonging its lifespan and reducing maintenance costs.

Design and Construction

The design and construction of hydrostatic rotary tables are critical to their performance and effectiveness. These tables are typically made from high-quality materials such as steel or aluminum to ensure durability and stability. The use of precision engineering techniques, such as CNC machining, is also common in the construction of hydrostatic rotary tables to ensure tight tolerances and smooth operation.

One of the key design features of hydrostatic rotary tables is the use of hydrostatic bearings. These bearings use pressurized oil to create a thin film of lubrication between the moving parts, reducing friction and allowing for smoother rotation. This results in higher levels of precision and accuracy in machining processes, making hydrostatic rotary tables ideal for industries where precision is paramount.

Benefits of Hydrostatic Rotary Tables

There are several benefits to using hydrostatic rotary tables in precision machining. One of the primary advantages is the high level of precision and accuracy that can be achieved. The use of hydrostatic technology allows for smoother rotation and tighter tolerances, resulting in superior quality and consistency in machined parts.

Another significant benefit of hydrostatic rotary tables is their durability and longevity. The use of hydrostatic bearings reduces wear and tear on the machinery, resulting in less frequent maintenance and repairs. This not only saves time and money but also ensures that the machinery remains in top condition for longer.

Applications

Hydrostatic rotary tables are commonly used in a variety of industries that require precision machining, such as aerospace, automotive, and medical device manufacturing. These tables are ideal for applications where tight tolerances and high levels of accuracy are necessary, such as the production of complex components and parts.

In the aerospace industry, hydrostatic rotary tables are often used in the manufacturing of components for aircraft engines and structures. The precision and accuracy of hydrostatic technology make these tables ideal for tasks such as drilling, milling, and grinding, where even the slightest deviation can have serious consequences.

In conclusion, the design and construction of hydrostatic rotary tables are crucial to their performance and effectiveness in precision machining. These tables offer a range of benefits, including high levels of precision and accuracy, durability, and longevity. They are commonly used in industries where precision is paramount, such as aerospace, automotive, and medical device manufacturing. If you are looking to improve the quality and consistency of your machining processes, consider incorporating a hydrostatic rotary table into your operations.

-

What Are the Ways to Choose the Tools for CNC Turning Lathe

Ⅰ. CNC turning lathe is a digital control system based on electronic computerCNC turning lathe is a digital control system based on an electronic computer, which is developed on the basis of traditio... -

Troubleshooting issues of CNC lathe

CNC lathe is one of the most widely used CNC machines. It is mainly used for cutting machining of axial parts or disc parts such as inner and outer cylindrical surfaces, inner and outer conical surfac... -

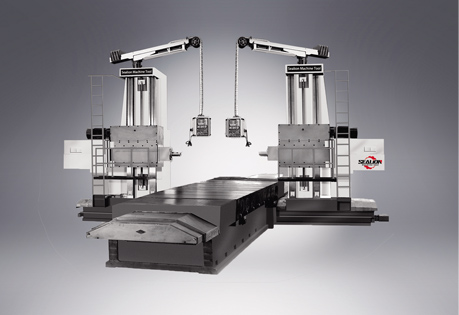

Precision and Accuracy Considerations in CNC Floor Boring Machines

In the world of manufacturing, achieving precision and accuracy is crucial. CNC floor boring machines have revolutionized the manufacturing industry by offering unparalleled accuracy and precision in ...