Precision and Accuracy Considerations in CNC Floor Boring Machines

In the world of manufacturing, achieving precision and accuracy is crucial. CNC floor boring machines have revolutionized the manufacturing industry by offering unparalleled accuracy and precision in creating complex parts. In this blog post, we will delve into the essential aspects of CNC floor boring machines, emphasizing the significance of accuracy and precision in their operations.

Understanding CNC Floor Boring Machines

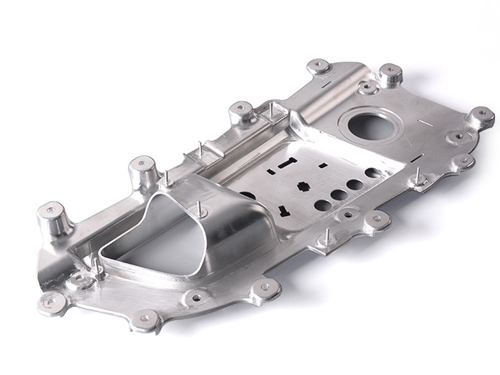

CNC floor boring machines are the epitome of technological advancements in the realm of manufacturing. These machines are designed to create precise and accurate holes, slots, and complex components in a wide range of materials, ensuring the highest standard of quality in the final product.

Key features of CNC floor boring machines include:

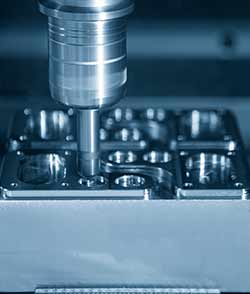

Numerical Control and Automation: CNC floor boring machines are operated via computer numerical control (CNC), allowing for the automation of drilling and machining processes. Programmed instructions ensure accurate and precise movements, minimizing human error.

Spindle Rotation and Feed Rates: CNC floor boring machines feature powerful spindles capable of high rotational speeds, while their feed rates can be customized to achieve precision in material removal. This flexibility enables the machine operator to attain optimal machining conditions for each specific job.

Advanced Tooling Options: CNC floor boring machines often possess multiple tooling options, including various drills, mills, and end mills. This versatile tooling capability presents manufacturers with the opportunity to perform diverse operations accurately and precisely, eliminating the need for manual intervention.

Accuracy Matters: Why CNC Floor Boring Machines are Imperative

Accurate machining plays a crucial role in the manufacturing process. Here are a few reasons why CNC floor boring machines are considered imperative for achieving accuracy:

Repeatable Accuracy: CNC floor boring machines provide unparalleled repeatability, allowing manufacturers to reproduce the same component with precise dimensions over multiple productions. This consistency guarantees uniformity, eliminating the risk of faulty parts and ensuring seamless assembly.

Enhanced Surface Finish: CNC floor boring machines offer exceptional control in material removal, resulting in impeccably smooth and uniform surface finishes. High-precision operations reduce the need for additional post-processing, thereby saving time, effort, and costs.

Reduction of Human Error: With CNC floor boring machines, the risk of human error is significantly reduced. Precise computer-controlled movements, elimination of manual intervention, and reduced reliance on operator skills contribute to enhanced accuracy, reducing the likelihood of human-induced mistakes.

Ensuring Precision in CNC Floor Boring Machines

To maximize precision in CNC floor boring machines, manufacturers need to consider the following factors:

Rigidity and Stability: The foundation and structure of CNC floor boring machines must offer exceptional rigidity and stability. Any vibrations or flexing during operation can compromise accuracy. High-quality construction materials, advanced design, and rigid foundations are vital elements for minimizing machine deflection.

Calibration and Maintenance: Regular calibration and maintenance are essential for ensuring the ongoing precision of CNC floor boring machines. Routine checks, alignment verification, and lubrication are imperative to keep the machine operating at its peak performance level and to maintain accuracy over time.

Skillful Programming: Accurate programming is the backbone of any CNC floor boring machine operation. Skilled programmers who understand the machine's capabilities and optimize the programming codes can further enhance precision and accuracy. Customizing feed rates, spindle speeds, and tooling options correctly are crucial aspects of programming.

As the demand for high-quality precision components continues to rise, CNC floor boring machines have made their mark in the manufacturing industry. Their exceptional accuracy and precision capabilities ensure consistent and immaculate results, leading to increased productivity, cost savings, and customer satisfaction. By considering the factors mentioned above, manufacturers can maximize the potential of CNC floor boring machines and reach new heights of accuracy and precision in their production processes.

-

Characteristics and Advantages of Different Types of CNC Machine Structures

CNC machines have revolutionized the manufacturing industry by streamlining processes and enhancing precision. One crucial aspect that influences their performance is their structure. In this blog, we... -

Workpiece Holding and Positioning Mechanisms in Horizontal CNC Rotary Tables

As technology advances, the demand for efficient and precise manufacturing processes continues to rise. Horizontal CNC rotary tables have become a popular choice for industries that require high-preci... -

Automobile manufacturing industry

Automobile manufacturing industryThe automobile industry is the locomotive driving the development of machine tool industry. The whole automobile manufacturing industry tests the overall level of prec...