What Are the Ways to Choose the Tools for CNC Turning Lathe

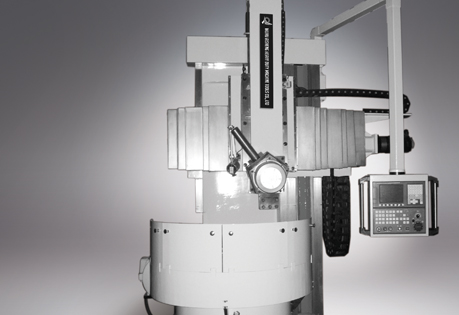

Ⅰ. CNC turning lathe is a digital control system based on electronic computer

CNC turning lathe is a digital control system based on an electronic computer, which is developed on the basis of traditional lathe, marking the beginning of machine tools into the era of CNC. Digital control technology in CNC mapping lathe is a technical method to control the movement of machine tools and their machining process with digital signals.

Ⅱ. What are the ways to choose the tools for CNC turning lathe

High-performance equipment is not only to ensure that the technology is advanced, but the configuration of facilities is also crucial. The accessories of CNC turning lathe mainly include tool fixture, operating parts, indexing head, table, chuck, joint, chip removal device, hose, drag chain, protective cover and so on. Among them, tool fixtures are divided into cutting tools, tooling fixtures, planing tools, CNC tools and supporting systems, tool belts, broaches, cutters, hobs, gear tools, machine saw blades, CNC tools, collets, punches, turning tools, reamers, boring tools, gear shanks, shaving tools, machine inserts, toolholders, milling tools, threaded tools, drills, toolholders, other tools, clamps, taps.

CNC turning lathe chooses the type of turning tools, according to the actual situation to screen. Currently, to achieve higher efficiency, high-speed and automation in CNC machine tools, we must pay higher attention to the selection of processing tools. Besides, the development of processing tools, with the continuous development of science and technology, has been deeper and presented the features of standardization, generalization and modularity.

Tool selection process starts from the "part drawing" to the "selected tool" to complete the tool selection process. The entire tool selection process has two different paths:

1. Part drawing, machine influence factors, selection of toolholder, inserting clamping system and selection of insert shape.

2. Routes: workpiece impact factors, selection of workpiece material code, determination of the insert chipbreaker slot type code or ISO chipbreaker range code, and selection of machining conditions face. The results of these two routes are combined to determine the selected tool.

-

Why is a CNC Machining Center More Suitable for Enterprises?

Ⅰ. CNC machining center has advantages over traditional instrumentsThe development of industrial technology speeds up the optimization of enterprises in the use of CNC machining center, which is in t... -

Daily Maintenance and regular inspection of Machining Center

In the use of equipment, daily maintenance and regular inspections are essential. Good maintenance can keep the equipment in a good working condition, improve production efficiency and reduce costs.1.... -

Components of Lathe Machine

Spindle box: also known as headstock, and its main task is to transfer the rotary motion from the main motor through a series of speed change mechanisms so that the spindle can get the required two ki...