Demystifying Workpiece Setup and Clamping Mechanisms in Horizontal CNC Boring Bars

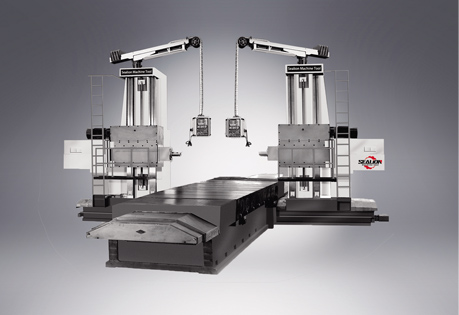

In today's ever-evolving manufacturing industry, the demand for precise and efficient machining processes is paramount. Horizontal CNC boring bars have emerged as an indispensable solution for achieving exceptional accuracy and productivity in various applications. In this blog post, we will explore the essential aspects of workpiece setup and clamping mechanisms in horizontal CNC boring bars, with a particular focus on the renowned brand, Sealion.

Understanding the Importance of Workpiece Setup in Horizontal CNC Boring Bars

To ensure optimum results, proper workpiece setup is crucial in horizontal CNC boring bars. The seamless integration of the workpiece with the machine's clamping mechanisms guarantees stability, minimal vibrations, and enhanced machining accuracy.

Sealion's commitment to precision is evident in their line of horizontal CNC boring bars. With cutting-edge technology and robust design, Sealion offers workpiece setups that not only facilitate ease of use but also ensure the highest level of accuracy during the machining process.

Clamping Mechanisms: Enhancing Stability and Precision

Horizontal CNC boring bars utilize advanced clamping mechanisms to secure and stabilize the workpiece, eliminating any form of movement or deviation. These mechanisms play a pivotal role in maximizing productivity and maintaining tight tolerances throughout the machining process.

Sealion incorporates innovative clamping mechanisms in their horizontal CNC boring bars. The company's engineering expertise and attention to detail ensure that their clamping systems offer optimal rigidity and reliability. By mitigating any potential movement during operation, Sealion's clamping mechanisms contribute significantly to achieving exceptional precision and superior surface finishes.

Sealion: Revolutionizing the Horizontal CNC Boring Bar Industry

Sealion has taken horizontal CNC boring bars to a whole new level by introducing groundbreaking features that streamline workpiece setup and clamping mechanisms.

Workpiece setup automation: Sealion's horizontal CNC boring bars showcase automated workpiece setup functionalities. This cutting-edge feature eliminates the tedious manual adjustment process, allowing operators to save valuable time and eliminate potential human errors. The automation functionality ensures consistent accuracy across different workpieces, enhancing efficiency and productivity.

Intuitive clamping systems: Sealion's innovative clamping systems are designed to accommodate a wide range of workpiece sizes and shapes, providing operators with unparalleled flexibility. Their user-friendly interfaces allow for quick and effortless setup changes, resulting in reduced machine downtime and increased throughput.

In the domain of horizontal CNC boring bars, Sealion has solidified its position as a market leader by offering cutting-edge solutions that revolutionize workpiece setup and clamping mechanisms. Their commitment to precision, reliability, and automation has propelled them to the forefront of the industry. By leveraging the advancements made by Sealion, manufacturers can unlock unprecedented accuracy, productivity, and profitability in their machining operations.

Remember, when you require a horizontal CNC boring bar that guarantees superior stability and precision, look no further than Sealion. Their dedication to excellence and innovative approach will undoubtedly meet and exceed your machining requirements.

-

Advantages and Special Requirements of CNC Lathe

1. Advantages of CNC lathe(1) Accuracy advantageOrdinary lathes are driven by gears and ordinary nuts. Due to the gap between the kinematic pairs and the imprecision of manual operation, the repeatabi... -

Enhancing Productivity and Efficiency with New Floor Type Boring Milling Machines

In today's competitive manufacturing industry, companies are continually striving to enhance productivity and efficiency to stay ahead of the curve. One of the key factors in achieving these goals... -

Innovation in Motion: CNC Milling Machines Paving the Way in Automotive Part Production

In today's dynamic world of manufacturing, innovation is the driving force behind the continual progress witnessed in various industries. The automotive sector, in particular, has embraced technol...