Innovation in Motion: CNC Milling Machines Paving the Way in Automotive Part Production

In today's dynamic world of manufacturing, innovation is the driving force behind the continual progress witnessed in various industries. The automotive sector, in particular, has embraced technological advancements to improve efficiency, precision, and overall productivity. This article will explore the role of computer numerical control (CNC) milling machines in revolutionizing automotive part production.

Revolutionizing the Automotive Industry with CNC Milling Machines

CNC milling machines have transformed the automotive industry by introducing automation and precision into the production process. Being programmable, these machines enable manufacturers to create intricate and complex automotive components, ensuring accuracy and consistency. The elimination of manual labor from the manufacturing process increases productivity, reduces errors, and ultimately leads to better-quality automotive parts.

The Unparalleled Precision of CNC Milling Machines in Automotive Part Manufacturing

One of the key advantages of CNC milling machines in automotive part production is their ability to achieve unparalleled precision. These machines utilize computer-aided design (CAD) software, wherein the desired specifications can be input, resulting in precise and accurate cuts. This level of precision is crucial for automotive components, which must fit perfectly together to ensure optimal performance and safety. CNC milling machines ensure that each part created adheres to the exact specifications, surpassing human capabilities.

Saving Time and Costs with CNC Milling Machines in the Automotive Sector

CNC milling machines contribute significantly to cost and time savings in the automotive industry. Traditional manufacturing techniques involve extensive manual labor and may require multiple iterations to achieve the desired outcome. CNC milling machines, on the other hand, eliminate human error and reduce the reliance on manual labor, resulting in streamlined production processes. The time saved can be utilized for other critical tasks, ultimately increasing productivity. Additionally, the reduction in errors minimizes the need for rework, thereby cutting down on production costs.

Exploring the Future Prospects of CNC Milling Machines in Automotive Part Production

As the automotive industry evolves, so too will the utilization of CNC milling machines. The incorporation of advanced technologies like artificial intelligence (AI) and machine learning promises a more efficient, autonomous, and intelligent manufacturing process. Features such as real-time data monitoring, predictive maintenance, and remote access will further enhance the capabilities of CNC milling machines, leading to continuous improvements in automotive part production.

The advent of CNC milling machines has brought a significant transformation to the automotive industry, revolutionizing the way automotive parts are manufactured. These machines provide unparalleled precision, enhance productivity, and have the potential to save both time and costs. As technology continues to advance, CNC milling machines are poised to play a crucial role in shaping the future of automotive part production, ensuring the industry can keep pace with the growing demands of efficiency, quality, and innovation.

-

The Requirements of CNC Lathes for Plant Environment Temperature

1. The requirements of CNC turning machines for plant environment temperatureCNC turning machines can efficiently process high-precision turning workpieces, and the processing methods also have functi... -

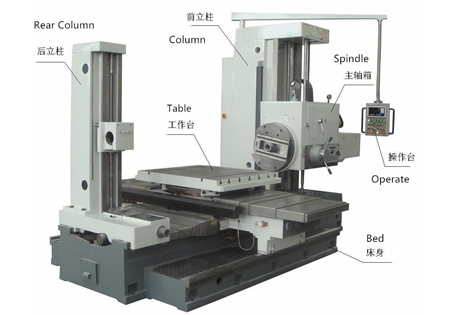

Causes of Machining Errors and Precautions for Operating a CNC Horizontal Boring Milling Machine

What Are the Reasons for the Machining Errors of CNC Horizontal Boring Milling Machines? The machining accuracy of CNC horizontal boring milling machine has problems. Is it only a problem with the ... -

What Are the Safety Operating Procedures for China CNC lathe machines?

Ⅰ. Inspection before starting the industrial lathe1. Add appropriate lubricating grease according to the industrial lathe lubrication chart.2. Check all electrical facilities, handle, transmission pa...CNC