How Floor Type Horizontal Borers Optimize Large-Scale Machining

In the world of large-scale machining, efficiency and precision are key factors that can make or break a project. Floor type horizontal boring machines have become a go-to solution for industries that require high-performance machining of large and heavy workpieces. In this blog, we will delve into the benefits, features, applications, and considerations of floor type horizontal borers.

Advantages of Floor Type Horizontal Boring Machines

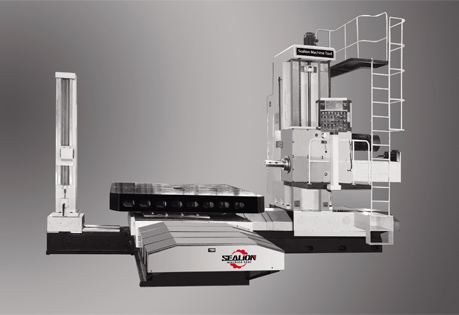

Floor type horizontal boring machines offer several advantages that make them ideal for large-scale machining operations. One of the main benefits is their robust construction, which allows them to handle heavy workpieces with ease. Their horizontal spindle orientation provides stability and accuracy, making them suitable for precision machining tasks. Additionally, their floor-level installation saves valuable floor space in the workshop, making them a practical choice for industrial settings.

Key Features of Floor Type Horizontal Borers

Floor type horizontal boring machines come equipped with a range of features that enhance their performance and efficiency. These machines typically have a sturdy bed and column design that minimizes vibration and ensures stability during machining operations. They also boast high spindle speeds and feed rates, allowing for faster and more accurate cutting. Many floor type horizontal borers are equipped with advanced control systems that offer programmable functions for increased automation and productivity.

Applications of Floor Type Horizontal Boring Machines

Floor type horizontal boring machines are widely used in industries such as aerospace, automotive, energy, and defense for a variety of machining applications. These machines are ideal for producing large components with complex geometries, such as engine blocks, turbine parts, and mold dies. They can also be used for deep hole drilling, boring, milling, and threading operations on materials ranging from steel and aluminum to hardened alloys and composites. Their versatility and precision make them indispensable tools for high-precision machining tasks.

Choosing the Right Floor Type Horizontal Borer for Your Machining Needs

When selecting a floor type horizontal boring machine for your machining requirements, there are several factors to consider. It is important to assess the size and weight of the workpieces you will be machining, as well as the level of precision and surface finish required. Additionally, consider the types of materials you will be working with and the specific machining operations you need to perform. Choose a machine with a suitable spindle speed, feed rate, and control system to ensure optimal performance and efficiency.

In conclusion, floor type horizontal boring machines are essential tools for optimizing large-scale machining operations. Their robust construction, high performance features, and versatility make them ideal for a wide range of industrial applications. By choosing the right floor type horizontal borer for your machining needs, you can achieve superior precision, efficiency, and productivity in your machining projects.

-

Green Precision: Sustainable Practices with Automated Milling in Eco-Friendly Production.

In the modern era, sustainability has become a pressing concern for industries all around the world. With the ever-increasing focus on environmental conservation, businesses are constantly seeking inn... -

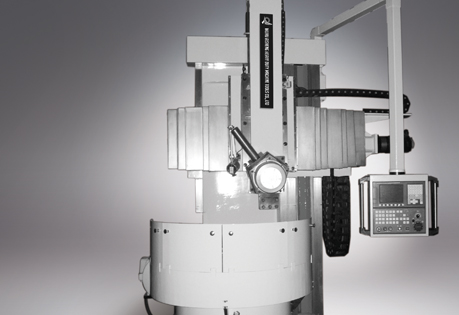

Components of Lathe Machine

Spindle box: also known as headstock, and its main task is to transfer the rotary motion from the main motor through a series of speed change mechanisms so that the spindle can get the required two ki... -

Changes Brought by the CNC Lathe Machine Development

The development of CNC machine tools not only reflects the development level of a country's modern manufacturing industry, but also is one of the important indicators to measure the development le...