Introduction and Classification of Vertical Machining Center

1. Introduction of Vertical Machining Center

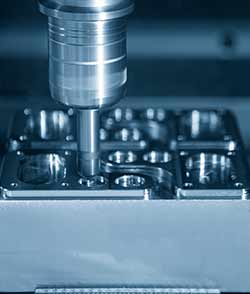

Vertical machining center refers to a machining center with the main shaft axis and the worktable perpendicular to it. It is mainly suitable for processing complex parts such as plates, plates, molds and small shells. The vertical machining center can complete processes such as milling, boring, drilling, tapping and cutting threads. The vertical machining center is at least three-axis and two-linkage, and generally can realize three-axis and three-linkage. Some can carry out five-axis or six-axis control. The height of the column of the vertical machining center is limited, and the processing range of box-like workpieces should be reduced. This is the shortcoming of the vertical machining center. But the vertical machining center is easy to clamp and locate the workpiece. The cutting tool movement track is easy to observe, the debugging program is convenient to check and measure, and the problem can be found in time, and the shutdown process or modification can be performed. The cooling condition is easy to establish, and the cutting fluid can directly reach the tool and the processing surface. The three coordinate axes are consistent with the Cartesian coordinate system, and the intuitive feel is consistent with the viewing angle of the drawing. The chips are easy to remove and fall to avoid scratching the processed surface. Compared with the corresponding horizontal machining center, the structure is simple, the floor space is smaller, and the price is lower.

2. Classification of vertical machining centers

(1) Classification according to guide rail

According to the form of the guide rail of each axis of the vertical machining center, it can be divided into hard rail and linear rail. The hard rail is suitable for heavy cutting, and the linear rail movement is more sensitive.

(2) Classification according to speed

The spindle speed of the vertical machining center is 6000-15000rpm for the low-speed type, and above 18000rpm is the high-speed type.

(3) Classification according to structure

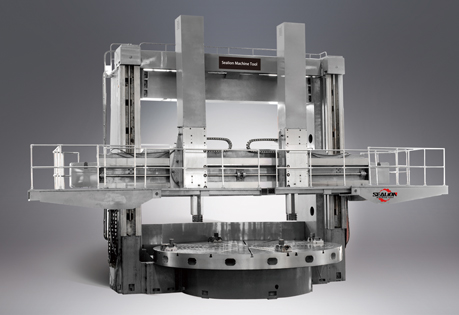

According to the bed structure of the vertical machining center, it can be divided into C type and gantry type.

3. Features of Vertical Machining Center

Vertical machining center refers to a machining center with a vertical spindle. Its structure is mostly a fixed column, the worktable is rectangular, and it has no indexing rotation function. It is suitable for processing disk, sleeve, and plate parts. It generally has three linear motion axis, and a rotary table rotating along the horizontal axis can be installed on the worktable to process spiral parts.

The vertical machining center is easy to install, easy to operate and observe the processing conditions, then debug the program, and has a wide range of applications. However, limited by the height of the column and the tool changer, some over high parts cannot be machined. When machining the cavity or concave profile, the chips are not easy to discharge. In severe cases, the tool will be damaged, the machined surface will be damaged, and the smooth processing will be affected.

-

How Does Machining Center Connect with Computer

CNC system of the machining center is often equipped with RS-232, CF card, DNC, Ethernet, and USB interface. How to connect the machining center with a computer depends on your CNC system and installa... -

Ai -Creation? Manufacture? Where Should The Development Of Machine Tool Industry Go In The Future?

industry from January to September decreased by 5.2% year-on-year, and that of measuring tool and meter industry from January to September increased by 2.3% year-on-year. China's machine tool indu... -

Innovation in Motion: CNC Milling Machines Paving the Way in Automotive Part Production

In today's dynamic world of manufacturing, innovation is the driving force behind the continual progress witnessed in various industries. The automotive sector, in particular, has embraced technol...