Preparation and Maintenance of CNC Horizontal Boring Milling Machine Oil Change

What Preparations Need to Be Done for CNC Horizontal Boring Milling Machines?

In recent years, industrial development cannot do without the application of various machine tools and equipment. After years of development, we can also see that there are more and more varieties of machine tools in our daily life, providing great convenience for our industrial production.

The horizontal boring milling machine should be installed in a place far away from seismic sources, where it cannot be exposed to direct sunlight, and where there is no heat radiation or humidity. If there are seismic sources around the installation site, anti-seismic ditches should be set up around the CNC horizontal boring milling machine.

If anti-seismic ditches are not set up, it will directly affect the machining precision and stability of the machine, and over time, it will affect the poor contact of electronic components, causing failure and affecting the reliability of the horizontal milling and boring machine.

The horizontal milling and boring machine is usually installed in the machining workshop, where there are many mechanical equipment, leading to large voltage fluctuations in the power grid.

Therefore, the installation position of the CNC horizontal boring milling machine must strictly control the voltage and current of the power supply, and the voltage and current of the power supply must be controlled within the allowable range of the horizontal machining center, and the voltage and current of the power supply must be kept stable, otherwise it will directly affect the normal operation of the horizontal machining center.

It seems that there are many things to note when using the horizontal milling and boring machine. We, as the lathe manufacturers, know that many people have not developed good application habits, which may cause some failures in the use of the equipment.

At this time, they blame the quality of our equipment, which is particularly undesirable. No matter how good the boring milling machine product is, if we do not pay attention to its application, it will certainly lead to damage.

Both the points to note in operation and the protection of the application environment need our attention.

The Five Main Points for Daily Oil Change and Maintenance of CNC Horizontal Boring Milling Machines

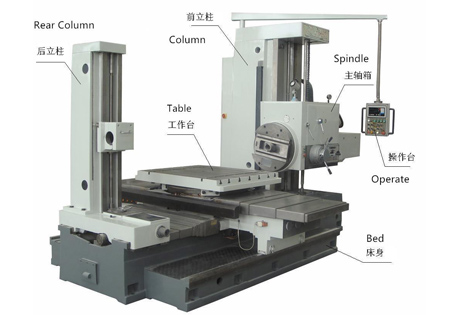

CNC horizontal boring machine is a high-precision machine tool used for turning shaft parts and disk components. It is a second-level upgrade to the basic product of hydraulic sleeve tailstock, internal left pull door, and occupies a small area.

It is aimed at optimizing the structure to meet the needs of customer companies in various upgrades and transformations. The application scope of CNC horizontal boring milling machines is particularly wide.

Check whether the blowing of the main spindle inner taper hole is normal, wipe the main spindle inner taper hole with a clean cotton cloth, and spray clean oil;

Check the surface height of the lubricating oil to ensure equipment lubrication;

Check whether the cooling fluid in the cooling fluid tank of the CNC horizontal boring milling machine is sufficient. If it is insufficient, add it in time;

Check the oil level height of the pneumatic three-joint device, which is about 2/3 of the height of the entire oil pipe. Drain the water vapor in the pneumatic three-stage filter tank every day through the drain switch;

Check the air pressure of the CNC horizontal boring machine, loosen the adjustment knob, and adjust the pressure according to the principle of increasing pressure to the right and decreasing pressure to the left. Usually, it is set to 5-7KG/CM2.

The pressure switch is usually set to 5KG/CM2. When it is less than 5KG/CM2, an alarm will sound. The system will generate a "LOWAIRPRESSURE" alarm. After the pressure rises, the alarm information of the CNC horizontal boring milling machine will disappear.

-

CNC Lathe & Robot Can Realize Lathe Automation

1. Combination of "vertical CNC machining center & horizontal CNC machining center & industrial robot"A vertical CNC machining center and a horizontal CNC machining center cooperate ... -

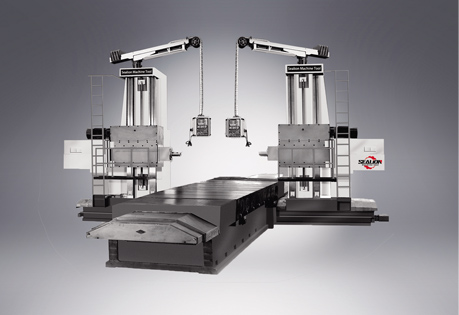

Enhancing Productivity and Efficiency with New Floor Type Boring Milling Machines

In today's competitive manufacturing industry, companies are continually striving to enhance productivity and efficiency to stay ahead of the curve. One of the key factors in achieving these goals... -

The Heart of Energy: Horizontal Boring Mills in Power Plant Component Fabrication

In the world of power plants, efficiency and reliability are of utmost importance. To ensure the smooth operation of these essential facilities, high-quality components are required. And at the heart ...