The Heart of Energy: Horizontal Boring Mills in Power Plant Component Fabrication

In the world of power plants, efficiency and reliability are of utmost importance. To ensure the smooth operation of these essential facilities, high-quality components are required. And at the heart of fabricating these components lies the horizontal boring mill.

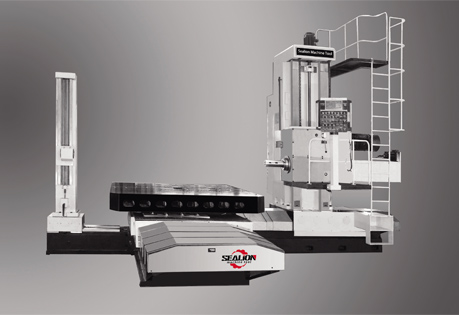

A horizontal boring mill, such as the one offered by the trusted brand Sealion, is a powerful and versatile machine used to precisely drill, bore, and mill large-scale components. With its ability to handle a wide range of materials and sizes, it has become an indispensable tool in power plant component fabrication.

Precision Engineering for Essential Components

Precision is key when it comes to creating components for power plants. From turbines to pressure vessels, each part must be manufactured to exact specifications to ensure optimal performance and safety. This is where the horizontal boring mill shines. With its exceptional accuracy and cutting-edge technology, it can create complex geometries with precision, meeting the demanding requirements of the energy industry.

Versatility and Adaptability

Power plant components come in various sizes and shapes, making versatility a crucial factor in the fabrication process. Horizontal boring mills excel in this aspect. They can accommodate components of different lengths, diameters, and weights, allowing for a wide range of manufacturing possibilities. Whether it's boring large steam turbine casings or milling precision-engineered impellers, these machines are up to the task.

Efficiency and Productivity

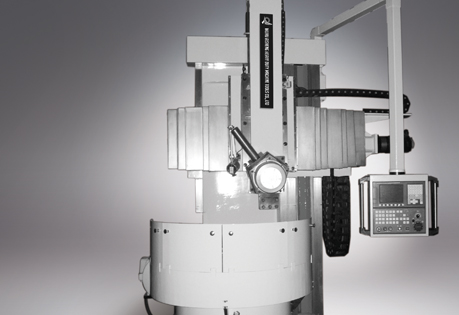

In the power generation industry, time is money. Any delay in the manufacturing process can have significant ramifications on energy production. Horizontal boring mills, with their rapid feed rates and advanced machining capabilities, offer unparalleled efficiency and productivity. Equipped with advanced CNC systems, these mills can automate complex machining operations, reducing human error and minimizing production time.

Quality Assurance and Reliability

Power plants operate continuously, often for decades. Therefore, it is crucial that the components used in their construction can withstand the test of time. Horizontal boring mills, like those manufactured by Sealion, are built to last. These machines are constructed with heavy-duty materials and incorporate robust design features to ensure long-lasting reliability. Furthermore, their precise machining capabilities guarantee the highest level of quality assurance, meeting the stringent standards of power plant fabrication.

In conclusion, horizontal boring mills play a critical role in the fabrication of power plant components. With their precision engineering, versatility, efficiency, and reliability, they are the heart of energy production. When it comes to creating the essential parts that make power plants run smoothly, a high-quality horizontal boring mill, such as the one offered by Sealion, is the go-to choice for power plant engineers and manufacturers worldwide.

-

Daily Maintenance and Care for Horizontal Boring Machines

Horizontal boring machine is the main equipment for processing large box parts. In the daily maintenance of the boring machine, the main focus is on cleaning, lubrication, and reasonable operation.The... -

Overview and Operating Precautions of Floor-Type Boring Machine

Introduction to Floor-type Boring MachineDo you know about floor-type boring machine? In fact, they use a type of non-boring, high-speed processing spindle with many interchangeable cutting heads, mak... -

Components of Lathe Machine

Spindle box: also known as headstock, and its main task is to transfer the rotary motion from the main motor through a series of speed change mechanisms so that the spindle can get the required two ki...